In the world of microfluidics, achieving a stable flow rate is paramount. Did you know that even minuscule variations in fluid dynamics can lead to significant discrepancies in experimental outcomes? For researchers and engineers alike, mastering flow control not only enhances the reliability of results but also accelerates innovation in applications ranging from drug delivery to environmental monitoring. In this guide, we’ll explore effective control strategies that streamline flow rates, ensuring precise and repeatable processes. By understanding the underlying principles and techniques-from passive methods to active feedback systems-you’ll be better equipped to tackle the challenges of microfluidic design and realize your project goals. Ready to dive in? A world of precise fluid manipulation awaits!

Understanding Microfluidics and Flow Rate Dynamics

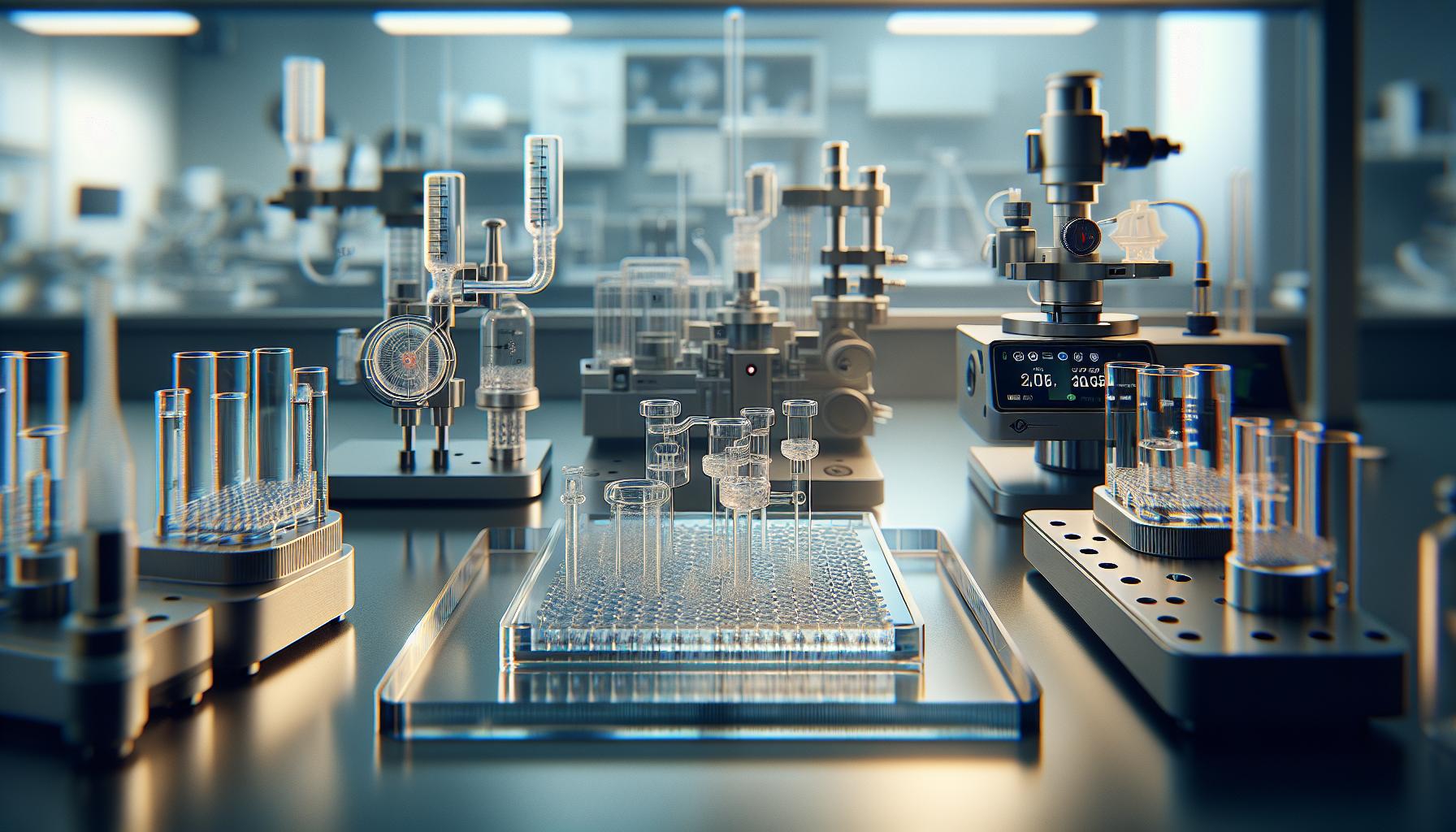

Microfluidics is an exciting field that enables precise control over fluid flow at the microscale, often leading to innovations in biomedical applications, chemical analysis, and environmental monitoring. A key aspect of achieving effective microfluidic designs is understanding the dynamics of flow rates, which can significantly impact the performance and stability of microfluidic systems. The behavior of fluids in microchannels is influenced not just by the intrinsic properties of the fluid, such as viscosity, but also by the geometry of the channel and the applied pressure gradients.

The flow rate in microfluidics is typically governed by the Hagen-Poiseuille equation, which expresses a linear relationship between pressure drop (ΔP) and flow rate (Q) through a channel of known resistance (R_h). This relationship underscores the importance of managing both the fluid properties and the microchannel design to ensure optimal flow. In practical terms, engineers must consider factors such as channel length, cross-sectional area, and the fluid’s viscosity, as these directly affect resistance and therefore flow stability. For instance, increasing the channel length or decreasing the radius can lead to higher resistance and reduced flow rates, which could compromise the efficacy of a microfluidic application.

Moreover, real-world microfluidic systems often deal with non-ideal conditions, such as varying fluid properties and external disturbances. Engineers can implement flow control strategies to maintain stable flow rates, including active feedback controls where sensors monitor flow and adjust pump speeds accordingly. Techniques such as pressure control, flow rate regulation, and even pneumatic actuation can come into play to ensure consistency, enabling reliable results in experiments where precision is paramount. As the field progresses, ongoing research focuses on innovative technologies that enhance flow stability, allowing for greater adaptability to the needs of various applications.

Understanding these dynamics and control mechanisms not only helps in optimizing existing systems but also paves the way for future advancements in microfluidic technologies. As researchers and practitioners embrace these principles, they open doors to new opportunities in diagnostics, drug delivery, and ultimately, personalized medicine. By examining the flow rate dynamics and strategically addressing them, you can significantly enhance the performance and reliability of microfluidic devices.

Key Factors Influencing Flow Stability

Microfluidic systems operate under conditions vastly different from bulk fluid dynamics, where even slight variations in parameters can lead to significant changes in flow stability. One of the primary factors influencing flow stability is the viscosity of the fluid being used. Fluids with higher viscosity present greater resistance to flow, which can produce erratic flow rates, especially in narrow microchannels. This resistance becomes crucial in applications requiring high precision, such as biological assays or drug formulation, where the accuracy of the fluid delivery must be tightly controlled. For instance, a viscous solution might require greater pressure differentials to achieve the same flow rate as a less viscous fluid, demanding careful adjustments in system design and control to maintain consistency.

Another vital aspect is the design and geometry of the microchannels themselves. The size, shape, and surface properties of the channels can create turbulence or laminar flow, directly affecting flow stability. Factors like channel width, depth, and the roughness of the channel walls introduce variations in resistance, which can lead to unpredictable flow rates. A well-optimized channel should minimize disruptions in flow by ensuring smooth transitions and appropriate scaling to manage expected flow rates. Engineers often utilize computational fluid dynamics (CFD) simulations to model these parameters before fabrication, aiding in creating designs that enhance stability under various operating conditions.

In addition to fluid properties and channel design, external factors play a significant role. Environmental conditions, such as temperature and pressure fluctuations, can affect fluid properties, further complicating the control of flow rates. For instance, temperature variations can change the viscosity of the fluid, leading to unexpected changes in flow behavior. Implementing insulated enclosures or temperature control systems can mitigate these effects, ensuring that the desired flow parameters remain stable throughout experiments. Moreover, vibrations from external sources can introduce noise in the readings of flow sensors, necessitating robust isolation techniques and careful placement of equipment to minimize such interferences.

Lastly, the choice of pumping mechanism is critical in maintaining consistent flow rates. Various pump technologies-such as syringe pumps, peristaltic pumps, or pressure-driven systems-have different characteristics affecting flow stability. For example, syringe pumps often provide more precise control over flow rates, but peristaltic pumps may be better suited for handling particulates without clogging. Understanding the strengths and limitations of each pumping strategy allows for better alignment with the specific requirements of the application, whether it’s for continuous flow or precise bolus delivery. By addressing these factors comprehensively, one can significantly enhance the stability and reliability of microfluidic systems, propelling advancements in diverse fields from diagnostics to drug delivery.

Control Strategies for Achieving Consistent Flow

To ensure consistent flow in microfluidic systems, implementing effective control strategies is essential. One compelling approach involves the integration of feedback mechanisms, which allow for real-time adjustments based on flow measurements. For instance, using flow sensors along with programmable controllers can automate adjustments to pump speeds or pressure settings in response to fluctuations detected within the system. This dynamic regulation minimizes the impact of variations from external environmental conditions or changes in fluid properties, significantly enhancing flow stability.

Utilizing Pump Technologies

The choice of pumping technology plays a pivotal role in flow control within microfluidics. Different pumps have unique advantages, and selecting the appropriate one based on the specific application can lead to enhanced flow consistency. For example, peristaltic pumps are particularly advantageous when handling sensitive biological samples, as they avoid shear stress and prevent clogging by using flexible tubing that conforms to the fluid’s pathway. Conversely, syringe pumps offer high precision for applications requiring meticulous control over flow rates, making them ideal for tasks such as drug delivery where accuracy is crucial.

Channel Design and Geometry

In addition to equipment choices, careful attention to channel design is critical for achieving consistent flow rates. Parameters such as channel dimensions, surface coatings, and geometrical configurations can either promote laminar flow or induce turbulence-each affecting the flow stability. Engineers often simulate fluid dynamics using computational tools to predict flow behaviors across various designs, optimizing them to reduce dead volumes and ensure smooth transitions. This consideration is especially vital in complex system arrangements where multiple channels interact.

By combining these strategies-feedback-based flow regulation, careful selection of pumping technology, and optimized channel design-researchers can vastly improve the reliability of microfluidic systems. This holistic approach not only mitigates the variability in flow rates caused by external and internal factors but also supports advancements in applications spanning from biochemical assays to innovative drug delivery systems. Each of these control strategies, tailored to the specific needs of the experiment, paves the way for enhanced performance and reproducibility in microfluidic applications.

Techniques for Flow Rate Measurement and Monitoring

To achieve precise flow rates in microfluidic systems, the measurement and monitoring of flow dynamics play a crucial role. Understanding fluid movement at such small scales can be quite complex, but with the right techniques and tools, researchers can ensure stable flow conditions essential for reliable experimental outcomes.

One effective method for measuring flow rates in microfluidics is the use of optical sensors, which employ laser or optical methods to detect the passage of fluid through microchannels. These sensors can be finely tuned to recognize changes in fluid properties, such as refractive index variations, providing real-time feedback on flow conditions. Moreover, ultrasonic flow meters are another popular option. They utilize sound waves to measure fluid velocity, particularly advantageous for non-intrusive monitoring. This technique is especially beneficial when dealing with opaque fluids or in applications where maintaining sterile conditions is vital.

In addition to direct measurement techniques, pressure sensors can provide indirect flow rate assessments. By monitoring the pressure difference across known resistances in the system, fluid flow rates can be calculated using the Hagen-Poiseuille equation. This approach not only promotes accuracy but is also particularly useful in systems where real-time data is required for dynamic control strategies.

To facilitate effective monitoring, implementing a data acquisition system that integrates these sensors is essential. Such systems can continuously log flow rates and provide alerts when parameters deviate from set thresholds, enabling swift corrective actions. For instance, coupling flow sensors with programmable controllers in a feedback loop allows for real-time adjustments, ensuring that microfluidic systems remain within the desired operating ranges even as variables shift. This combination of measurement techniques and robust monitoring systems not only enhances flow stability but also drives improvements across a range of applications, from biochemical analysis to drug delivery.

Modeling Fluid Dynamics in Microfluidic Systems

is crucial for understanding and predicting how fluids behave in these tiny channels. At such small scales, conventional fluid dynamics principles must be adapted, as effects like viscosity and surface tension become significantly pronounced. Therefore, accurate modeling uses equations governing laminar flow and complex fluid interactions to ensure that microfluidic systems operate effectively.

One popular approach is using the Navier-Stokes equations, which describe the motion of fluid substances. These equations take into account the fluid’s viscosity, velocity, and pressure, enabling precise simulations of flow under various conditions. Computational Fluid Dynamics (CFD) software can simulate these equations to visualize how changes in channel design or fluid properties affect flow rates. This method allows engineers and researchers to optimize designs before physical prototypes are built, saving both time and resources.

Key Considerations for Modeling

Several factors influence the accuracy of fluid dynamics models in microfluidic systems:

- Channel Geometry: The shape and dimensions of microchannels can dramatically impact flow patterns and resistances. For instance, sudden expansions or contractions in channel width can lead to flow disturbances.

- Fluid Properties: The viscosity and density of fluids used in microfluidics can alter flow behavior. Non-Newtonian fluids, where viscosity changes with shear rate, require additional considerations in modeling.

- Temperature Effects: Temperature can influence fluid properties; thus, models must include thermal effects, particularly in bioapplications where temperature control is crucial.

In addition to using well-established equations, one effective strategy involves implementing boundary conditions that replicate the operational environment of the microfluidic device. This approach enhances model fidelity, providing insights into how real-world variables-such as pressure fluctuations or flow interruptions-may affect flow rates.

Real-World Application of Modeling Techniques

To exemplify practical applications of fluid dynamics modeling, consider the use of CFD in designing a droplet microfluidic device. Researchers simulate various configurations to determine how fluid mixtures interact when formed into droplets. By visualizing droplet formation and breakup, they can also optimize flow rates to ensure consistent droplet sizes crucial for applications in diagnostics or drug delivery.

By embracing these modeling techniques, researchers and developers can uncover new insights into microfluidic flow dynamics. They can create predictive models that guide the design of more robust systems, ultimately leading to improved performance and reliability in various applications, from pharmaceuticals to environmental monitoring.

Addressing Challenges in Flow Rate Control

Achieving a stable flow rate in microfluidic systems can present unique challenges due to the complex nature of fluid dynamics at such small scales. One of the primary issues stems from the dominance of laminar flow, where disruptions in flow can lead to significant variations in fluid behavior. Factors like microchannel geometry, fluid properties, and external environmental influences can all introduce instability. For example, small changes in pressure can cause unexpected fluctuations in flow rates, potentially compromising the outcomes of sensitive experiments, especially in applications like biological assays or chemical reactions.

Mitigating these challenges involves employing various strategies to monitor and regulate flow dynamically. Utilizing precise flow sensors can provide real-time data on flow rates, allowing for immediate adjustments. Implementing feedback control systems is crucial; these systems can automatically adjust the pumping mechanisms based on the data received, ensuring that flow rates remain within desired parameters. For instance, a pressure controller coupled with a syringe pump can help maintain consistent flow rates even when dealing with variable liquid viscosities or changes in temperature.

Additionally, optimizing channel design is essential for enhancing flow stability. This includes not only the physical dimensions of the channels but also their surface properties. Techniques like surface modification can reduce unwanted interactions between the fluid and channel walls, minimizing effects like fluid trapping and backflow that disrupt stable flow conditions. By carefully considering these design elements and integrating advanced monitoring technologies, researchers can effectively address challenges in flow rate control, leading to improved performance and consistency in microfluidic applications.

Overall, combining meticulous design with robust monitoring and automatic control strategies can significantly enhance the reliability of flow rates in microfluidics, paving the way for more predictable and effective outcomes in research and industrial processes.

Implementing Feedback Mechanisms for Flow Regulation

In the intricate world of microfluidics, ensuring a stable flow rate is not merely a goal-it’s a necessity. Feedback mechanisms stand out as vital tools for achieving and maintaining this stability, acting like auto-pilots that fine-tune flow conditions in real-time. The efficacy of these systems can make the difference between successful experimental outcomes and frustrating inconsistencies, especially in sensitive applications such as diagnostics or chemical synthesis.

To ensure a reliable flow rate, feedback control systems continually monitor the parameters that influence flow dynamics. These can include pressure, temperature, and flow rates themselves. A typical setup integrates sensors, which relay data back to a controller. Upon detecting deviations from set parameters, the control system makes immediate adjustments to the pump settings or valve positions. For instance, if a drop in flow rate is detected due to viscosity changes, the feedback mechanism can alter the pumping speed to compensate. This real-time responsiveness is crucial in microfluidic applications where even minor variations can lead to significant errors.

Real-World Applications

Consider a practical example in droplet generation for digital microfluidics, where precise droplet formation is essential. By implementing a feedback loop that monitors droplet size and frequency, researchers can dynamically adjust flow rates to optimize the dispensing process. This adaptive control reduces the risk of droplet merging or formation failure, ultimately boosting its application for high-throughput screening in biomedical research.

Key Considerations

Implementing these mechanisms involves careful selection of components and calibration strategies. Key considerations include:

- Sensor Selection: Choose sensors that provide high accuracy and response speed.

- Control Algorithms: Utilize advanced algorithms (like PID controls) that can handle the complexities of nonlinear fluid dynamics.

- System Integration: Ensure seamless integration between sensors, controllers, and pumps to minimize lag and errors.

Overall, the integration of feedback mechanisms in microfluidic systems not only enhances the precision of flow rate control but also paves the way for innovative applications across numerous scientific fields. By leveraging these technologies, researchers can bridge the gap between theory and practical execution, leading to faster discoveries and more robust experimental outcomes.

Innovative Technologies for Enhanced Flow Stability

Existing and emerging technologies continue to revolutionize flow stability in microfluidic systems, addressing many challenges that researchers face in achieving precise and consistent fluid control. One notable trend is the integration of advanced microvalve systems, which allow for rapid and accurate adjustments in flow rates. These microvalves are often piezoelectric or electrostatic, enabling quick on/off responses and precise modulation of fluid volumes. With the ability to achieve micrometer-level control over fluids, these systems significantly enhance the stability of flow compared to traditional methods.

In addition to microvalve advancements, the development of digital microfluidics has transformed the landscape of flow control. This approach utilizes dielectrophoresis to manipulate discrete droplets of liquid on a surface, offering unparalleled control over timing and placement. By harnessing electrical fields, researchers can effectively manage flow without the need for pumps, which can introduce vibrations or create inconsistencies. This technique not only improves flow stability but also lends itself well to high-throughput applications, making it ideal for biomedical research and diagnostics.

Hybrid Systems for Optimal Performance

The emergence of hybrid systems, combining passive and active flow control methods, showcases innovative approaches to enhancing flow stability. For instance, combining pressure-based methods with feedback systems allows for robust control that adapts to varying conditions. By integrating sensors that monitor real-time environmental parameters with robust control algorithms, researchers can fine-tune flow dynamics to accommodate changes in fluid properties, such as viscosity or temperature fluctuations.

Technological innovations also extend to artificial intelligence and machine learning applications in microfluidics. These technologies analyze data from flow monitors in real time, predicting and adjusting flow rates to overcome potential disturbances proactively. Such smart systems can identify patterns and make adjustments faster than traditional methods, ensuring that flow remains consistent even in dynamic experimental setups. This capability can significantly reduce human error and optimize reproducibility across experiments.

Finally, the utilization of 3D printing technology in the fabrication of microfluidic devices allows for the rapid prototyping of customized flow channels and control mechanisms. This flexibility not only accelerates the development process but can also lead to complex geometries that enhance flow laminarity and reduce dead volumes. As researchers explore innovative designs, the potential for improved flow stability increases, paving the way for future advancements in microfluidics.

Innovative technologies will continue to drive the evolution of flow stability in microfluidic applications, combining precision engineering with intelligent control systems for transformative results.

Case Studies: Successful Flow Control Applications

In the rapidly evolving field of microfluidics, real-world case studies illustrate how advanced flow control techniques enable groundbreaking solutions across various applications. One notable example can be found in the realm of biomedical diagnostics. Researchers at a leading institute developed a microfluidic device capable of analyzing blood samples for disease markers in a matter of minutes. By employing a combination of pressure-based flow control and smart microvalve systems, they were able to precisely regulate fluid flow, ensuring that reagents interacted with samples at optimal rates. This implementation not only improved diagnostic accuracy but also significantly enhanced throughput, empowering healthcare providers with timely results for better patient care.

Another compelling case study originates from environmental monitoring, where microfluidic devices have been utilized to detect contaminants in water sources. An innovative device was designed to continuously pump water samples through a series of microchannels that house sensors capable of identifying specific pollutants. By integrating feedback control mechanisms, the system automatically adjusts flow rates based on real-time sensor data, ensuring consistent sample integrity even under varying environmental conditions. This adaptive control approach proves essential for accurate monitoring and demonstrates the versatility of microfluidics in addressing critical ecological issues.

In the pharmaceutical sector, companies are leveraging microfluidic systems for drug development and delivery. One pioneering firm utilized a digital microfluidics platform to create a high-throughput screening system for drug compound interactions. The technology enabled precise control over individual droplets of liquid, allowing researchers to test thousands of compounds in a fraction of the time required by traditional methods. This not only accelerated the drug discovery process but also minimized the use of resources, reducing costs while maximizing efficiency. The application of such targeted flow control strategies exemplifies the transformative potential of microfluidics in developing the next generation of therapeutics.

The discussion surrounding these case studies underscores the importance of stable flow rates in microfluidic systems. As illustrated, successful applications hinge on effective control strategies that prioritize precision and adaptability. From diagnostics to environmental monitoring and drug development, the integration of advanced flow control techniques is not just enhancing current capabilities; it is redefining what is possible in scientific research and practical applications. As the field continues to innovate, maintaining a focus on stable flow rates and dynamic control will be crucial for realizing the full potential of microfluidic technologies.

Future Trends in Microfluidic Flow Control Strategies

As we look ahead in the realm of microfluidics, several exciting trends are shaping the future of flow control strategies. One compelling development is the integration of artificial intelligence (AI) in microfluidic systems. AI can analyze vast amounts of data generated by fluid dynamics, enabling real-time adjustments to flow rates and enhancing the responsiveness of microfluidic devices. This capability not only improves experimental precision but also allows for smarter, self-optimizing systems that can adapt to changing conditions, thus achieving greater stability in flow rates.

Another trend is the use of advanced materials and fabrication techniques, such as 3D printing and soft lithography, which facilitate the creation of intricate channel designs that can manipulate fluid dynamics more effectively. These innovations enable researchers to experiment with new geometries and layouts, optimizing flow paths to minimize disruptions and enhance laminar flow. For instance, bio-inspired designs that mimic natural structures can lead to more efficient mixing and transport characteristics, crucial for applications in drug delivery or environmental sensing.

Emerging Technologies for Stabilization

Coupled with these advancements, there is a growing interest in microvalve and droplet-based technologies for precise flow regulation. Microvalves controlled through electrokinetic or thermal methods offer the ability to finely tune flow rates on demand. Similarly, digital microfluidics, which control the movement of discrete droplets, are paving the way for high-throughput experimentation, enabling rapid screening of multiple conditions with minimal sample volumes. This flexibility is particularly beneficial in pharmaceutical research and diagnostics, where reaction conditions can be quickly adjusted without the need for extensive setup changes.

Moreover, the implementation of feedback mechanisms, such as closed-loop control systems, stands out as a critical strategy for achieving consistent flow rates. By integrating sensors that monitor flow characteristics alongside automated control systems, researchers can maintain stability even in fluctuating environments. These systems can proactively adjust operational parameters, ensuring that flow rates remain within desired thresholds for optimal performance.

The Path Forward

As we advance, collaboration across disciplines will be crucial in bringing these innovations to fruition. Partnerships between materials scientists, engineers, and biologists can foster new ideas and approaches that address the multifaceted challenges of microfluidics. Engaging with academic research and industry advancements will also play a key role in translating theoretical insights into practical applications. Ultimately, the future of microfluidic flow control lies in our ability to harness these trends, integrate cutting-edge technologies, and respond to the evolving needs of various scientific fields.

By embracing these dynamic developments, researchers can push the boundaries of what is possible in microfluidics, leading to more stable and efficient systems that meet the demands of modern scientific inquiry and application.

Comparative Analysis of Control Methods

Achieving stable flow rates in microfluidic systems is critical for various applications, from biomedical assays to chemical synthesis. Different control methods vary in complexity, precision, and suitability for specific tasks. Understanding these nuances helps researchers and engineers select the best approach for their needs.

One primary method is the pressure-based control, which utilizes pressure-driven flow for precise regulation. Pressure controllers, like those from Fluigent, allow for rapid adjustments and maintain consistent flow despite changes in system dynamics. This method excels in applications requiring high accuracy, such as cell culture and droplet microfluidics. However, it can be sensitive to variations in channel geometry, necessitating careful design and calibration.

In contrast, syringe pumps are among the most common flow controllers used historically in microfluidics. They provide a straightforward means of controlling flow rates by mechanically moving fluid through syringes. While they offer simplicity and reliability, syringe pumps can struggle with high viscosity fluids and may not respond rapidly enough to dynamic changes in flow demands.

Digital microfluidics, which manipulate discrete droplets on surface tension-based platforms, present a novel approach to flow control. This method allows for precise control over droplet movement and mixing, making it ideal for high-throughput applications. However, it requires careful management of droplet formation and transport, which can complicate system design.

Integrating feedback mechanisms is a crucial strategy across all these methods. Closed-loop control systems can adjust the input based on real-time flow measurements, enhancing stability and reducing oscillations. By employing sensors that track flow characteristics, researchers can actively compensate for disturbances, leading to more reliable outcomes.

As technology progresses, new innovative methods, like electrokinetic flow control, are emerging. These techniques leverage electric fields to manipulate fluid motion at the microscale, offering advantages such as reduced mechanical components and the potential for greater miniaturization. Nevertheless, these systems require a different set of design considerations, such as electrode placement and material compatibility.

In summary, the choice of flow control method depends on specific application requirements, including desired precision, fluid properties, and the operational environment. A comparative analysis of these methods helps researchers optimize their microfluidic systems for enhanced performance, pushing forward the frontiers of microfluidics research and applications.

Best Practices for Microfluidic Design and Optimization

Achieving stability in microfluidic flow rates is critical for successful experimentation and application across various fields such as biology, chemistry, and materials science. A key aspect lies in the thoughtful design of the microfluidic system itself. By implementing best practices in design and optimization, researchers can significantly enhance flow consistency and overall performance.

To start, channel design plays a vital role in ensuring smooth flow. Narrow channels can create resistance and lead to pressure fluctuations. Therefore, engineers should aim for a balance between channel width and flow requirements, keeping in mind the properties of the fluids being used. Utilizing CAD software for simulation can help visualize fluid dynamics and identify potential bottlenecks before physical implementation.

Material selection is another crucial factor. Choosing biocompatible or chemically resistant materials based on the intended application can prevent unwanted reactions or degradation that might affect flow rates. For instance, polydimethylsiloxane (PDMS) is popular for its flexibility and ease of fabrication in biological applications, but for chemical synthesis, materials resistant to solvents, such as glass or thermoplastics, might be preferred.

Incorporating robust sensor technology offers another layer of optimization. Real-time monitoring of flow rates through pressure sensors or optical sensors can provide instantaneous feedback. This allows for immediate adjustments to the control system, thus maintaining desired flow rates even under varying experimental conditions. Additionally, integrating closed-loop control systems can refine response accuracy and overall stability. Such systems not only adjust flow rates but also help in validating the consistency of results, a critical factor in quantitative experiments.

Furthermore, engaging in proper maintenance of the microfluidic device is essential for sustained performance. Regular cleaning protocols to prevent clogging or biofouling, along with periodic recalibration of pumps and sensors, can significantly mitigate variations in flow rates over time.

By adhering to these best practices, researchers can streamline their microfluidic processes, ensuring not only reliable results but also the potential for innovative applications in diverse scientific fields.

FAQ

Q: What are common control strategies for stabilizing flow rates in microfluidic systems?

A: Common control strategies for stabilizing flow rates include using peristaltic pumps, implementing feedback control systems, and utilizing pressure control methods. These strategies ensure consistent flow by adjusting pump speeds or pressure based on real-time data, enhancing the precision of microfluidic applications.

Q: How does viscosity affect flow stability in microfluidics?

A: Viscosity plays a crucial role in flow stability; higher viscosity fluids tend to yield more stable flows due to lower rates of turbulence. To achieve stable flow rates, it may be necessary to select appropriate fluids or adjust channel dimensions to accommodate varying viscosities in your microfluidic design.

Q: When should feedback control mechanisms be implemented in microfluidic systems?

A: Feedback control mechanisms should be implemented when precision and consistency are critical, especially in applications involving delicate biological samples. They help monitor and adjust flow rates dynamically, ensuring that the desired conditions are maintained throughout the experiment.

Q: What techniques can be used to measure flow rates in microfluidics?

A: Techniques for measuring flow rates in microfluidics include capacitance-based sensors, optical flow measurements, and magnetic resonance methods. These techniques enable real-time monitoring, allowing researchers to detect deviations immediately and adjust parameters for optimal flow stability.

Q: Why is it important to control shear stress in microfluidic applications?

A: Controlling shear stress is vital because excessive shear can damage sensitive cells and affect biochemical reactions. Implementing flow control strategies that stabilize shear stress levels ensures that biological applications are safe and effective, preserving cell integrity for accurate research outcomes.

Q: What are the challenges in achieving stable flow rates in microfluidics?

A: Key challenges include variability in fluid properties, channel geometry issues, and external environmental factors. Overcoming these challenges requires careful design and regular monitoring to detect fluctuations and implement necessary adjustments to maintain stable flow.

Q: How can system design impact flow rate stability in microfluidics?

A: System design significantly affects flow rate stability. Factors like channel dimensions, tubing quality, and junction configurations can lead to pressure drops or turbulence. A well-optimized design minimizes these issues, supporting smoother fluid dynamics and more reliable flow rates.

Q: What are future trends in microfluidic flow control strategies?

A: Future trends in flow control strategies focus on integrated sensing technologies, AI-based flow modeling, and adaptive control systems. These advancements aim to improve responsiveness and precision in flow management, making microfluidic systems more efficient and versatile for various applications.

The Conclusion

Achieving a stable flow rate in microfluidics is crucial for ensuring the reliability of your experiments and applications. By implementing the control strategies discussed, you empower your projects with precision and consistency. Don’t let variable flow rates compromise your results-take action today to refine your techniques and optimize your systems.

Explore related resources like our in-depth guide on “Advanced Microfluidic Device Design” and our article on “Common Pitfalls in Microfluidics,” which can further enhance your understanding and application of these concepts. If you’re keen to dive deeper, consider subscribing to our newsletter for the latest insights, or visit our consultation page for personalized support. Share your thoughts in the comments below-let’s foster a community of innovation and expertise in microfluidics together. Your journey to mastering flow control starts now!