Microfluidic chips are revolutionizing fields like healthcare and environmental monitoring by enabling precise analysis and manipulation of tiny fluid volumes. Understanding the cost of these innovative devices is crucial for researchers, startups, and established companies alike. Factors influencing microfluidic chip pricing include material choices, manufacturing processes, and the complexity of design.

As technology advances, the pressure to balance cost and performance grows, making it vital for stakeholders to grasp the financial landscape of microfluidics. This guide will not only break down costs but also explore how careful planning and design can lead to more effective solutions while staying within budget. Whether you’re a researcher looking to prototype or a business aiming to integrate these chips into products, understanding these elements will empower you to make informed decisions. Keep reading to uncover essential insights that could shape the future of your projects.

Understanding Microfluidic Chip Costs in Detail

Understanding the costs associated with microfluidic chips is crucial for researchers, developers, and companies looking to leverage this innovative technology. Microfluidic chips, which allow for the manipulation of fluids at a microscale, are not just a singular product but rather a combination of various components, each contributing to the overall cost. This complexity often leads to a wide range of prices, influenced by factors such as material choice, design intricacies, and production scale.

The basic components of microfluidic chips include substrates, typically made from glass or polymers, microchannels, pumps, valves, and sensors. For example, a simple chip with fewer features may cost around $50 to $100, while more advanced, custom-designed chips with integrated sensors can range from thousands to tens of thousands of dollars. Each component’s cost varies significantly based on the materials used and the engineering required for the design.

One of the most significant influences on pricing is the complexity of the chip’s design. Chips that require intricate channel patterns or specialized functions, such as mixing or separation capabilities, often lead to increased fabrication costs. Moreover, the scale of production plays a vital role in pricing; larger production runs can lower costs due to economies of scale, while small, bespoke orders may incur higher prices. Understanding these elements enables stakeholders to make informed decisions on budgeting and selecting between custom or off-the-shelf solutions, ultimately impacting the project’s financial viability.

As technology continues to evolve, new manufacturing methods and materials emerge, promising to reshape the cost landscape for microfluidic chips. Future trends may include enhanced automation in production, which could streamline processes and reduce costs further, making these powerful tools more accessible to a broader audience. Keeping an eye on these developments can aid in planning and optimizing expenses for upcoming projects.

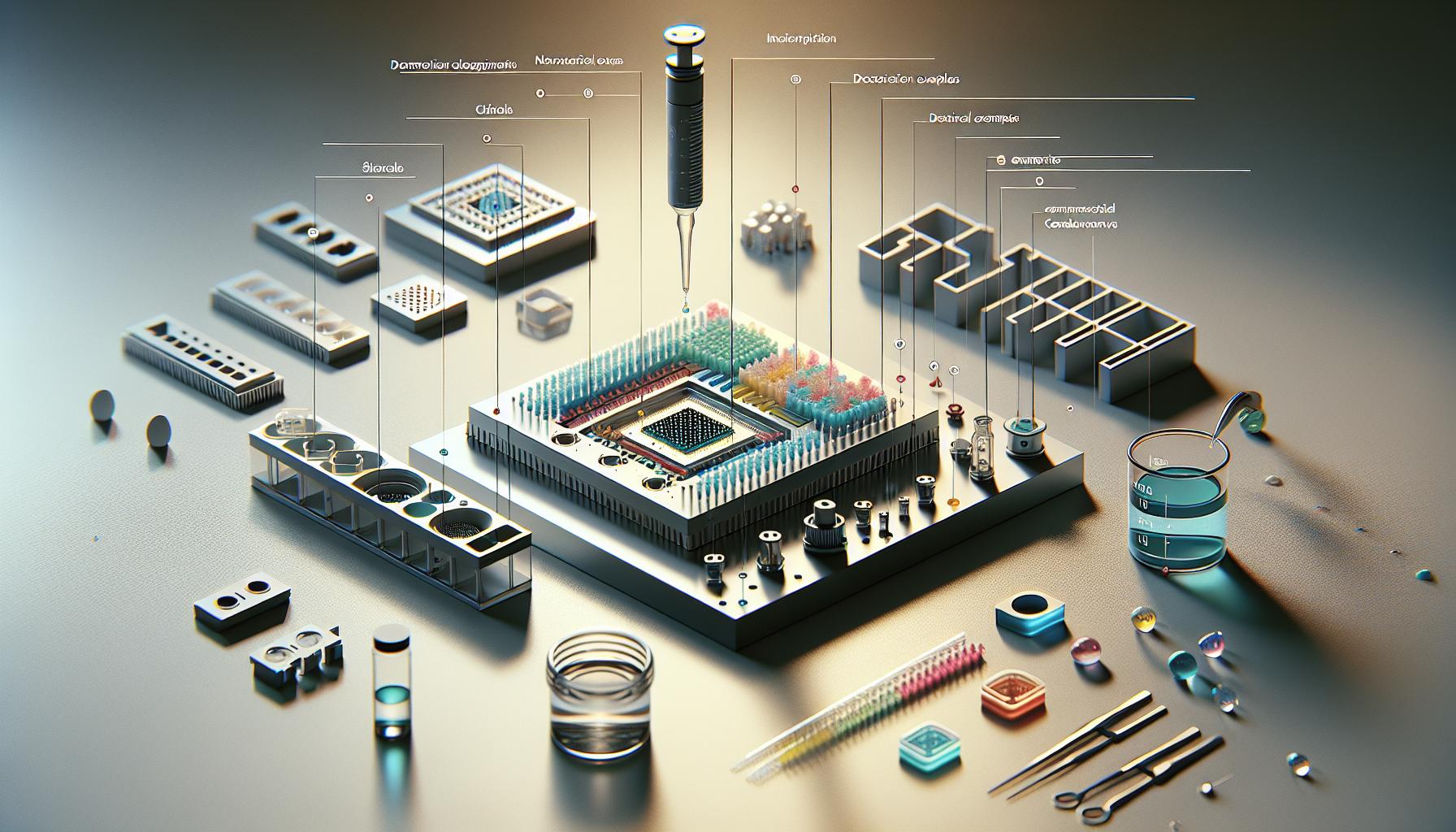

Breakdown of Microfluidic Chip Components

Microfluidic chips are marvels of engineering, combining precision and technology to manipulate tiny volumes of fluids with remarkable accuracy. Understanding the specific components that comprise these chips can demystify their pricing and functionality for researchers and developers alike. Each component plays a critical role in the chip’s overall performance and cost, making it essential to grasp their individual contributions.

The primary building blocks of a microfluidic chip include the substrate, microchannels, pumps, valves, and sensors. Typically, substrates are made from materials such as glass or polymers like PDMS (polydimethylsiloxane), each offering distinct advantages in terms of transparency, chemical resistance, and ease of fabrication. Microchannels, which facilitate fluid movement, vary in dimensions and design complexity, impacting both performance and cost. A basic design might feature straight channels, while advanced configurations could include branching, mixing zones, or specific geometries for enhanced fluid dynamics.

Pumps and valves are crucial for regulating flow rates and pressures within the microfluidic system. These components may be integrated on-chip or used as external devices, affecting the overall chip size and manufacturing complexity. For applications requiring precise volume control and fast response times, the integration of advanced sensors can significantly enhance functionality. The choice of sensors, whether optical, electrochemical, or pressure-based, further contributes to the chip’s overall pricing structure.

As you evaluate microfluidic chip options, consider that a more sophisticated design-incorporating intricate features or integrated functionalities-will inherently increase fabrication costs. Advanced manufacturing techniques, such as soft lithography, 3D printing, or injection molding, can lead to variations in pricing based on tooling and setup costs. Understanding this breakdown not only helps in budgeting effectively but also aids in making informed decisions about which chip design aligns best with project requirements and financial constraints.

Key Factors Influencing Microfluidic Chip Prices

Microfluidic chips are not just a marvel of innovation; they also represent a complex interplay of various factors that determine their pricing. Whether you’re a researcher in a lab or a startup looking to develop groundbreaking applications, understanding what influences these costs can significantly impact your procurement decisions and overall project budgets.

One significant factor is materials selection. Different substrates like glass and polymers offer varying properties that affect both functionality and cost. For instance, while glass might provide superior optical clarity, it is often more expensive to produce compared to polymers like PDMS. Additionally, the choice of materials for microchannels and sensors can lead to increased expenses, especially if specialized treatments or coatings are involved.

Moreover, the design complexity of the chip plays a crucial role in pricing. A simple chip with basic channel designs will typically be less expensive to manufacture than one that requires intricate, multilayer constructions or integrated components. As designs become more sophisticated, incorporating features like pumps and valves, the costs can escalate due to the need for advanced fabrication techniques and tooling. For example, soft lithography might be used for simpler chips, whereas more complex designs could necessitate 3D printing or injection molding processes, each with distinct cost implications.

The scale of production is another pivotal factor. Economies of scale can lead to significant cost reductions when producing microfluidic chips in high volumes. Conversely, custom, low-volume chips often attract higher per-unit costs due to the initial setup and tooling expenses that are spread over fewer units. This pricing dynamic makes it essential for developers to evaluate their project needs against potential production scales.

Finally, technological advancements continue to influence the pricing landscape of microfluidic chips. Innovations that enhance manufacturing efficiency, reduce material waste, or improve device performance can either lower costs or justify higher prices based on increased functionality. As the industry evolves, staying informed about these trends can provide a strategic advantage in budgeting and development planning.

Addressing these key factors allows various stakeholders-from academia to industry-to navigate the landscape of microfluidic chip pricing with confidence and clarity, ensuring that their projects align cost-effectively with the evolving technological landscape.

Comparing Custom vs. Off-the-Shelf Microfluidic Chips

When it comes to microfluidic chips, choosing between custom designs and off-the-shelf solutions can significantly impact not only the project’s budget but also its timeline and overall effectiveness. Off-the-shelf chips usually offer a quicker route to implementation as they are readily available and have been pre-tested for various applications. This option is ideal for researchers or developers in need of a reliable and cost-effective solution without the complexity of a bespoke design. For instance, a common selection would be standard microfluidic devices used in diagnostics or cell culture, which can save both time and resources for projects that align with their pre-defined specifications.

On the other hand, custom microfluidic chips are tailored to meet specific project requirements and can incorporate unique features or alterations that enhance functionality for particular applications. Though the initial costs for custom chips may be higher due to design and fabrication efforts, they can lead to better performance and results in specialized applications. For example, a lab developing a microfluidic device for a novel biomedical application might need unique channel structures or integrated sensors that are not available in off-the-shelf models. This adjustment allows researchers to scale their innovations, thus potentially leading to breakthroughs in their respective fields.

Cost Considerations

The cost implications of choosing between custom and off-the-shelf chips can vary significantly. Off-the-shelf chips often come at a lower purchase price, making them appealing for limited budgets or exploratory projects. Conversely, the design and prototype fees associated with customizing a chip can be a significant investment. Custom chips might include costs related to design software, rapid prototyping, and advanced manufacturing techniques-expenses that can justify the price through enhanced accuracy or efficiency in the intended applications.

Ultimately, the decision rests on the specific needs of a project. Developers should evaluate their project’s requirements, budget constraints, and long-term goals. It’s prudent to conduct a thorough needs analysis before deciding, balancing factors like immediate availability against the potential benefits of increased functionality in a custom chip. Each option has its merits, and the right choice will enhance the development process, facilitate faster results, and align with the researcher’s vision for their microfluidic applications.

The Role of Material Choices in Cost Variation

Material selection in the development of microfluidic chips plays a crucial role in determining both performance and cost. The choice of materials not only influences the manufacturing process but directly affects the chip’s scalability, durability, and suitability for specific applications. With a myriad of materials available-from polymers like PDMS (polydimethylsiloxane) to glass and silicon-each comes with its own benefits and challenges that can significantly impact overall project budgets.

Using PDMS, for instance, is popular for rapid prototyping due to its easy molding capabilities and biocompatibility, making it a cost-effective choice for many applications. However, it can be less stable over time compared to glass or silicon options, which, while more expensive, offer superior chemical resistance and longevity. The trade-off between initial cost and long-term durability can be pivotal; researchers might save money upfront by choosing PDMS but may face higher costs down the line if the chips require frequent replacements or adjustments.

Material Cost Factors

Several factors contribute to the variation in material costs for microfluidic chips:

- Material Type: Different materials have varying costs. High-performance materials like borosilicate glass or specialized polymers can drive up prices compared to standard plastics.

- Availability: The local availability of materials can influence shipping costs and lead times, impacting the overall project budget.

- Processing Techniques: Some materials require advanced fabrication techniques, which can be expensive and time-consuming, thus influencing the cost further.

Ultimately, making informed material choices is essential for balancing performance requirements with budget constraints. Effective collaboration with materials scientists and engineers during the planning phase can yield significant insights into which materials will provide the best outcomes for both cost and functionality. As the field of microfluidics advances, emerging materials and methods may offer new opportunities for innovation, making ongoing education and research into material properties an invaluable asset for developers looking to optimize their projects economically and effectively.

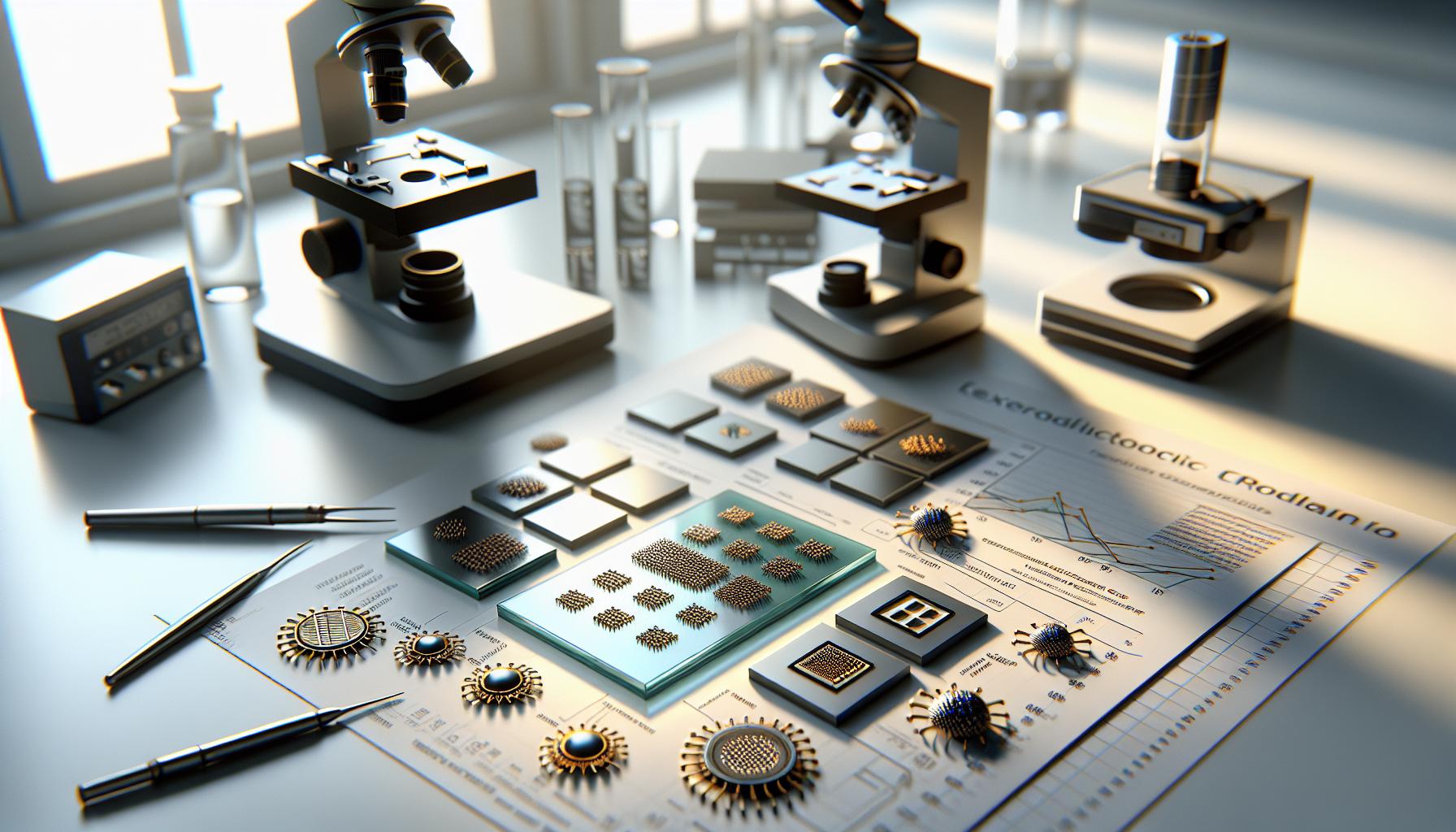

Cost Implications of Chip Design Complexity

The complexity of microfluidic chip design holds significant implications for costs that researchers and engineers must carefully navigate. As designs become more intricate, the associated expenses can escalate rapidly. One major factor in this relationship is the advanced technologies and techniques that are often required for creating complex features on microfluidic devices. These technologies, while enabling innovative functionalities like precise fluid manipulation or integration of sensors, often involve specialized equipment and skilled labor, both of which contribute to higher production costs.

In the realm of chip design, customization plays a crucial role. Custom-designed chips can offer highly specific functionalities tailored to unique experimental needs, but this level of specialization comes with a price. The complexity of designing and validating these chips not only prolongs the development timeline but also incurs expenses related to additional prototyping, testing, and potential redesign. Failures in the prototyping phase, common with complex designs, can further exacerbate costs due to wasted materials and labor.

Moreover, the material and fabrication choices associated with complex designs cannot be ignored. Advanced design often requires the use of high-performance materials that are more expensive than conventional options. For example, intricate geometries might necessitate materials with superior thermal stability or chemical resistance, leading to additional material costs. Fabrication techniques like hot embossing or lithography, which are vital for achieving fine features, can also be more time-consuming and resource-intensive compared to simpler methods, adding another layer to the total expense.

To mitigate these costs, employing design software that aids in simulations and optimizations can be invaluable. By using these tools, designers can identify potential issues early in the design process, ultimately saving time and reducing costs associated with rework. Additionally, collaborating closely with fabrication partners early in the design process can yield insights on the most cost-effective ways to achieve desired complexities, ensuring that budget constraints are respected while still pushing the boundaries of what’s possible in microfluidic technology.

Economies of Scale in Microfluidic Production

The production of microfluidic chips embodies the principle of economies of scale, where increased production leads to lower costs per unit. This concept is particularly significant in microfluidics, as the technology often involves costly materials and intricate manufacturing processes. As companies scale their production volumes, they can spread fixed costs-such as research, development, and equipment investment-over a larger number of units, reducing the average cost of each chip.

Moreover, higher production levels can lead to significant improvements in manufacturing efficiency. When a specific design goes into mass production, manufacturers can refine their processes, reducing waste and optimizing resource utilization. For instance, established suppliers often have the infrastructure to execute rapid prototyping that is cost-effective at scale. They leverage advanced techniques such as Injection Molding or Continuous Flow Microfabrication, which can produce large quantities of chips in shorter timeframes compared to traditional batch methods. These advancements not only expedite the production process but also enhance the uniformity and reliability of the chips produced, appealing to researchers who prioritize consistency in experimental results.

Another critical aspect to consider is supplier negotiation power that comes with higher volumes. Companies that order microfluidic chips in bulk often receive volume discounts on materials and components, further driving down costs. They may also benefit from prioritized production schedules and improved lead times, an essential factor when aligning project timelines in fast-paced research environments.

However, achieving these economies necessitates careful planning and commitment. Transitioning from small-scale development to larger production runs requires upfront investment and a thorough understanding of the manufacturing landscape. Thus, researchers and engineers should consider their projected needs early in the design process, factoring in potential scalability from the outset to harness these cost reductions when it comes time to manufacture. By balancing their design ambitions with a clear production strategy, stakeholders can significantly enhance their project’s financial feasibility while pushing the boundaries of microfluidic innovation.

Impact of Technology on Microfluidic Pricing

The rapid evolution of technology plays a pivotal role in shaping the pricing landscape of microfluidic chips. As advancements in manufacturing techniques and materials arise, they dramatically affect both production costs and market pricing. For instance, innovations such as 3D printing and advanced photolithography allow for more precise and efficient chip fabrication, often resulting in lower labor costs and reduced material waste. These technologies enable manufacturers to create complex chip geometries and custom designs that were previously impractical or cost-prohibitive.

One key factor is the adoption of automation in the production process. Automated systems, including robotics and computer-controlled machinery, streamline manufacturing workflows and minimize human error. This efficiency not only accelerates production timelines but also contributes to significant savings, which can be passed on to customers. For example, companies employing automated assembly lines can achieve higher throughput while ensuring consistent quality, thus supporting a scalable production model that aligns well with market demands.

Additionally, the ongoing development of materials science is influencing microfluidic chip pricing. The introduction of novel materials, such as flexible polymers or biocompatible substances, expands the functionality of chips and allows for applications that were not feasible with traditional materials. However, the initial costs of these advanced materials may be higher, impacting the overall pricing of the chips. It’s essential for researchers and developers to weigh the short-term costs against the potential long-term benefits provided by enhanced performance and capabilities.

As the microfluidic industry continues to mature, keeping an eye on technological advancements is crucial for stakeholders. By embracing new technologies and materials, manufacturers can enhance their production efficiency, reduce costs, and ultimately lead to more competitive pricing for microfluidic products. This dynamic interplay between innovation and pricing underscores the importance of adopting forward-thinking strategies in both development and procurement.

Long-Term Cost Considerations for Users

Understanding the long-term financial implications of investing in microfluidic chips is essential for researchers, developers, and companies navigating this innovative landscape. While the initial purchase price of microfluidic chips may be a factor in decision-making, the ongoing costs associated with maintenance, scalability, and adaptability can significantly impact overall project budgets.

One critical area is recurrent operational costs. Microfluidic devices often require specific reagents and consumables, which can add up over time. For example, a project may begin with a small-scale prototype using limited functionality, but as research progresses, the need for more complex protocols and higher volume testing may necessitate additional expenditures. Budgeting for these consumables is crucial since they can vary widely depending on the chip’s application, such as diagnostics or drug delivery systems.

Another long-term consideration is maintenance and support costs. As technology evolves, older chip designs may become obsolete or incompatible with newer equipment or software platforms. Users must assess not just the durability of the chips themselves but also the vendor’s support policies. Having access to upgrades, technical support, and service agreements can mitigate disruption and additional costs in the future. This approach ensures that investments remain viable as technology advances.

Finally, scalability should be carefully planned. Costs may increase as production scales, particularly if custom chips are involved. It’s essential to evaluate whether the selected microfluidic chip can be adapted to larger scales or if transitioning to a different production method is required as the project grows. This decision can affect both unit costs and total project budgets in the long run.

As you embark on a microfluidic project, remember that looking beyond the initial purchase price to consider the total life-cycle costs will provide a clearer financial picture and help ensure sustainable success in your research or application.

Estimating Budget for Microfluidic Projects

Estimating the budget for microfluidic projects requires more than just tallying up the initial costs of the chips themselves; it involves a comprehensive understanding of multiple factors that can influence the overall financial commitment. With microfluidic technologies still evolving, securing a well-informed budget is paramount to navigate this dynamic landscape effectively. One captivating aspect to consider is how even minor design choices can lead to significant variations in total costs across projects.

A successful budget should encompass hardware costs, which include the purchase or leasing of microfluidic chips, necessary equipment like pumps and sensors, and specialized software for data analysis. Additionally, don’t overlook reagents and consumables, as these represent ongoing expenses that often escalate over time-especially as projects scale or shift focus. It’s crucial to estimate these costs early, utilizing a cost model that reflects your project’s specific demands, whether for diagnostics, therapeutic applications, or research purposes.

Understanding Hidden Costs

When preparing your budget, consider the hidden costs associated with training personnel and maintaining equipment. The integration of new technologies often necessitates significant training for users to ensure effective operation. As such, allocating funds for training sessions or workshops can be essential for maximizing efficiency and avoiding costly operational errors. Additionally, the longevity and maintenance of your microfluidic systems can incur unexpected costs; always account for service agreements or potential repairs in the budgeting phase.

Another dimension of budgeting is to forecast scalability needs. If your project anticipates an increase in scope-such as transitioning from research phases to clinical trials-evaluate how many additional chips and associated supplies will be required. Planning for larger production runs often leads to cost efficiencies through bulk purchasing but may initially seem daunting. By preparing a realistic projection that charts expected cost increases against operational complexities, you can create a more resilient budget.

Ultimately, meticulous planning that includes all variables-from direct costs to hidden expenses-will help demystify the budgeting process for microfluidic projects. By placing equal emphasis on current needs and future developments, you’ll be better equipped to manage financial resources effectively, ensuring ongoing success in the innovative realm of microfluidic technology.

Future Trends in Microfluidic Chip Pricing

As the microfluidics field continues to evolve, so too does the landscape of pricing for microfluidic chips. The interaction of technological advancements, material science innovations, and market dynamics is reshaping how costs are determined. For instance, as production methodologies improve, particularly through automation and miniaturization, we can expect to see a gradual decrease in manufacturing costs-a trend driven by increased efficiency and reduced labor expenses. In scenarios where production can be scaled, bulk manufacturing is likely to yield significant cost reductions, ultimately making microfluidic chips more accessible to a broader range of users.

One compelling trend is the shift towards off-the-shelf solutions. As the demand for standardized microfluidic platforms rises, manufacturers are responding by offering pre-designed chips that can serve a variety of applications. The appeal of these off-the-shelf chips lies not only in their immediate availability but also in their reduced development costs compared to custom solutions. However, the trade-off may involve sacrificing the degree of specificity that tailored chips can provide. Researchers and developers now face the crucial decision of balancing cost with the need for specificity, a choice that could affect the overall outcome of their projects.

Additionally, new materials are entering the microfluidic arena, enhancing chip performance while potentially reducing costs. For instance, the development of new polymers and glass compositions aims to create chips that are not only more cost-effective but also offer improved fluidic control and stability. These advancements promise to broaden the application of microfluidic technologies, from diagnostics to therapeutic uses, thus increasing demand and fostering competition in the market, which can further stabilize or reduce prices over time.

In summary, the future of microfluidic chip pricing will likely reflect a combination of technological innovations, material developments, and market forces. As these elements converge, stakeholders from researchers to manufacturers can prepare for a more competitive pricing structure, emphasizing the need for efficient budgeting and strategic planning in microfluidic project development.

Frequently asked questions

Q: What are the average prices for microfluidic chips in different applications?

A: The average prices for microfluidic chips vary significantly based on their application, ranging from $1 to $1000 per chip. For instance, basic diagnostic chips may cost around $20, while specialized research chips can exceed $500. Understanding specific application needs can help in estimating budget allocations effectively.

Q: How do production methods affect the cost of microfluidic chips?

A: Production methods significantly influence microfluidic chip costs. For example, mass production using injection molding is often more cost-effective than laser machining or 3D printing, which are typically used for smaller batches. Optimizing production methods can lead to substantial savings in high-volume applications.

Q: Are there hidden costs when purchasing microfluidic chips?

A: Yes, hidden costs may include shipping fees, customization charges, and setup expenses for specialized designs. Additionally, expenses related to testing and integration into existing systems should also be factored in to ensure comprehensive budgeting.

Q: What types of microfluidic chip materials affect pricing?

A: The material used in microfluidic chips plays a crucial role in their pricing. Common materials include glass, silicon, and thermoplastics, with costs ranging from low to high depending on the desired durability and application specifics. For instance, silicon tends to be more expensive due to its processing requirements.

Q: What is the impact of customization on microfluidic chip prices?

A: Customization can significantly increase the cost of microfluidic chips. Depending on design complexity and required features, prices can inflate by 20-300% compared to off-the-shelf options. Evaluating the necessity of custom features can bolster cost efficiency.

Q: How does the scale of production impact microfluidic chip costs?

A: The scale of production greatly affects microfluidic chip costs, with larger-scale productions benefiting from economies of scale. Higher production volumes typically result in reduced per-unit costs, making it more economical for companies aiming for widespread application.

Q: Are there financial assistance options for microfluidic chip projects?

A: Yes, there are several financial assistance options such as grants, crowdfunding, and partnerships with research institutions. Exploring these avenues can mitigate upfront costs associated with microfluidic chip development and production.

Q: How often should microfluidic chip technology be evaluated for cost effectiveness?

A: It’s advisable to evaluate microfluidic chip technology for cost effectiveness annually or when significant advancements occur. Regular assessments help in identifying opportunities for cost reductions and ensure that the latest technologies and production methods are being employed.

Future Outlook

In summary, understanding the cost breakdown of microfluidic chips is crucial for researchers and innovators looking to leverage this technology. Remember, while initial investments can seem daunting, the potential efficiencies and advancements in various applications-from medical diagnostics to environmental monitoring-are well worth the pursuit. Don’t let uncertainty hold you back; dive deeper into the world of microfluidics now.

If you found this breakdown insightful, check out our related articles on “The Future of Microfluidic Technologies” and “Cost-Effective Strategies for Incorporating Microfluidics in Your Research.” These resources can further equip you with the knowledge you need to make informed decisions.

Take the next step: subscribe to our newsletter for the latest insights, or explore our product offerings that can empower your projects today. Your journey into the cutting-edge realm of microfluidic devices starts here-don’t miss out! Engage with us in the comments below; we’d love to hear your thoughts or questions.