Have you ever wondered how a hot pot transfers heat to a cooler surface? This fascinating phenomenon is known as conduction, the transfer of heat through direct contact. Understanding conduction is crucial not just in cooking, but also in various fields such as engineering, physics, and everyday life. When we grasp the principles of heat transfer, we can innovate better insulation materials, improve energy efficiency, and optimize cooking techniques. By delving deeper into this topic, you’ll discover the underlying theories and practical applications that make conduction a vital concept in both science and daily activities. Join us as we explore the nuances of heat transfer through direct contact and uncover its significance in our world.

What Is Heat Transfer Through Direct Contact?

Heat transfer through direct contact-often referred to as conduction-is a fundamental process that occurs when two materials at different temperatures are in physical contact. The thermal energy naturally flows from the hotter object to the cooler one until they reach thermal equilibrium. This process is not just an academic concept; it’s something we encounter in our daily lives. For instance, consider the simple act of touching a hot pan. The heat flows from the pan into your hand, demonstrating conduction in action.

One key principle of conduction is that the efficiency of heat transfer depends on the materials involved. Metals, such as copper and aluminum, are excellent conductors of heat due to their atomic structure, which allows electrons to move freely and transfer energy efficiently. In contrast, materials like wood or plastic are poor conductors, termed insulators, because their molecular structure does not allow for easy energy transfer. This difference in conductivity is why oven mitts, often made from insulating materials, are essential when handling hot cookware.

A variety of factors influence the rate of heat transfer through conduction, including the temperature difference between the materials, the cross-sectional area in contact, and the distance heat must travel. The equation governing this transfer can be represented using Fourier’s law of heat conduction, which states that the rate of heat transfer (Q) is proportional to the thermal conductivity (k), the area (A), and the temperature gradient (dT/dx):

| Parameter | Description |

|---|---|

| Q | Rate of heat transfer |

| k | Thermal conductivity of the material |

| A | Cross-sectional area through which heat flows |

| dT/dx | Temperature gradient (change in temperature per unit distance) |

Understanding these principles not only clarifies how heat transfer works but also guides practical applications in engineering and technology. For instance, in designing thermal management systems for electronics, engineers must consider materials that enhance conductivity to efficiently dissipate heat, preventing overheating and ensuring optimal performance. By grasping the concept of heat transfer through direct contact, we unlock insights into both everyday experiences and advanced technological innovations.

Understanding Conduction: The Basics of Heat Transfer

When we touch a hot stove, the heat that rushes into our hand is a perfect demonstration of how conduction works. This process of heat transfer through direct contact occurs whenever two objects at different temperatures meet. Thermal energy moves naturally from the hotter object to the cooler one until they reach a state of equilibrium, where both objects settle at the same temperature. This simple principle is fundamental across a wide range of everyday activities and technological applications, from cooking to electronics.

Conduction relies heavily on the materials in contact. Metals, like copper and aluminum, excel at conducting heat due to their atomic structure, which allows electrons to move freely and carry thermal energy. In contrast, materials like wood, plastic, or rubber are considered insulators; they hinder the flow of heat. This is why you typically use oven mitts (often made from insulating materials) when handling hot pots or pans. The choice of materials in any heating or cooling application dramatically impacts efficiency and safety, making an understanding of these properties crucial in fields such as engineering and material science.

Several factors influence the efficiency of heat transfer by conduction. Key among them is the temperature difference between the two materials, as a larger difference typically enhances the rate of heat transfer. Additionally, the area of contact plays a crucial role; a larger surface area allows more heat to flow. Lastly, the distance heat must travel through the material matters-shorter distances generally lead to faster conduction. These relationships can be quantitatively expressed through Fourier’s law of heat conduction, which provides guidelines for calculating the rate at which heat is transferred based on material properties and conditions.

In practical applications, engineers harness these principles to improve performance in various technologies. For example, in electronics, selecting materials with high thermal conductivity helps dissipate heat efficiently, preventing overheating and ensuring reliability. By comprehending the basics of conduction, we can better appreciate its effects in everyday life while also applying this knowledge to innovate and improve technological designs.

Real-World Examples of Heat Transfer by Conduction

To truly understand how heat transfer through direct contact manifests in our daily lives, one must look closely at common experiences where conduction is at play. From the kitchen to the workplace, conduction illustrates itself in ways that are both practical and significant. For instance, when a metal spoon is placed in a hot pot of soup, the heat travels from the soup to the spoon. As the spoon warms up, the heat continues to be conducted from the hotter end submerged in the soup to the cooler end held out of the pot, demonstrating how effectively metals transfer thermal energy due to their atomic structure. This is not just a curious response; it reflects essential principles used in cooking and food safety.

Another everyday example is the use of frying pans. When you heat a pan on a burner, the heat is conducted through the material of the pan. Cookware materials like cast iron or stainless steel are designed to maximize this effect. The effectiveness of heat conduction influences how evenly food cooks and can impact the results of your culinary endeavors. A well-conducting pan ensures that food is not only heated swiftly but also uniformly, reducing the chances of scorching on one side while leaving the other undercooked.

In the realm of construction and design, the principles of conduction are critical for energy efficiency. Building materials are chosen for their thermal properties to minimize energy loss. For example, insulating materials like fiberglass or foam boards are utilized in walls to hinder heat conduction, keeping indoor environments warm during the winter and cool in the summer. This strategic interplay highlights the importance of understanding heat transfer in optimizing energy use and promoting sustainability.

When looking to improve conduction in various applications, consider factors such as material selection and surface area. For instance, in electronic devices, manufacturers often incorporate heat sinks made from metals with high thermal conductivity, like aluminum or copper, to manage heat build-up. This not only protects sensitive components but also enhances the overall efficiency and longevity of the device. Understanding these real-world examples of conduction allows individuals and organizations to make informed decisions in cooking, construction, and technology efficiently.

Key Factors Influencing Heat Transfer Efficiency

Understanding how heat transfer efficiency can be influenced by various factors is crucial for optimizing processes in cooking, manufacturing, and technology. One of the most immediate factors affecting heat transfer through direct contact is the material’s thermal conductivity. Metals such as copper and aluminum have high thermal conductivity, allowing them to transfer heat quickly and effectively, making them ideal for cookware and heat exchangers. In contrast, materials like wood or plastic have much lower conductivity, which results in slower heat transfer and is often used when insulation or heat resistance is required.

Another important aspect is the surface area in contact between the two materials. The greater the surface area, the more efficient the heat transfer. For instance, using a griddle instead of a flat pan can provide a larger area for heat transfer, resulting in evenly cooked food. In engineering, the design of heat exchangers often incorporates fins or extended surfaces to maximize heat transfer by increasing the area through which heat can move.

Temperature Gradient

The temperature difference between the two objects also plays an essential role. A larger temperature gradient-meaning a noticeable difference in temperature between the heat source and the object receiving heat-will generally result in more efficient heat transfer. For example, when a hot metal pot is placed on a cold stovetop, the heat will transfer more rapidly than if the stovetop is also warm. Understanding this principle is key in applications like refrigeration, where managing temperature gradients can enhance overall efficiency.

Finally, the presence of any insulating materials or air gaps can significantly hinder heat transfer. Air pockets are often poor conductors of heat, and this is why materials like styrofoam are used in construction for insulation. In electronics, eliminating air gaps between heat sinks and components can enhance thermal management in devices. By recognizing these influential factors-thermal conductivity, surface area, temperature gradient, and insulative barriers-one can design and employ systems that optimize heat transfer for better performance and efficiency.

Differences Between Conduction, Convection, and Radiation

Understanding how heat moves through different mediums is essential, especially when considering practical applications. Heat transfer occurs in three main forms: conduction, convection, and radiation, each with distinct mechanisms and impacts on how efficient that transfer can be in real-world scenarios.

Conduction is the process of heat transfer through direct contact between materials. This occurs when high-energy particles in a hot object collide with lower-energy particles in a cooler object, transferring energy in the process. For example, when a metal spoon is placed in a hot pot of soup, heat from the soup is conducted through the spoon’s material, making it warm to the touch. Conductive materials, typically metals like copper and aluminum, have high thermal conductivity, enabling them to transfer heat efficiently. Conversely, insulators like wood and plastics have low conductivity and resist heat transfer, making them useful in applications where heat retention or barrier is desired.

Convection: Moving Heat Through Fluids

While conduction requires direct contact, convection involves the movement of heat through fluids (gases or liquids). When a fluid is heated, it becomes less dense and rises, while cooler fluid replaces it, creating a cycle known as a convection current. For instance, when heating water on a stove, warmer water rises to the surface while cooler water descends, creating a constant circulation of heat. This mechanism is crucial in various systems, from heating buildings to industrial processes, and is typically more efficient than conduction due to the bulk movement of the fluid.

Radiation: Heat Transfer Without Medium

Radiation is a unique mode of heat transfer that does not require any medium; it occurs through electromagnetic waves. This is how the Sun heats the Earth despite the vacuum of space. All objects emit some level of thermal radiation based on their temperature, and this form of heat transfer can occur even in a perfect vacuum. For example, infrared heaters use radiation to warm a space without needing to heat the air first, making them effective for direct heating applications.

Understanding these differences aids in optimizing heating and cooling systems, enhancing energy efficiency, and improving designs across technologies, from home appliances to industrial machinery. Whether you’re developing new equipment or just trying to stay warm during winter, recognizing how these processes function can provide invaluable insights into managing heat effectively.

Applications of Conduction in Everyday Technology

The transfer of heat through direct contact, known as conduction, plays a crucial role in the functioning of various everyday technologies that we often take for granted. From your morning coffee to the intricate design of modern electronics, conduction is at the heart of thermal management in countless applications. By understanding how conduction operates, we can appreciate the essential role of thermal conductors and insulators in our devices and daily lives.

One of the most relatable applications of conduction is in cooking. When using pots and pans, materials with high thermal conductivity, such as copper and aluminum, are preferred because they heat quickly and distribute heat evenly. For instance, a copper-bottomed saucepan will warm up faster than a stainless-steel one. This efficiency is vital for precise cooking, helping to prevent hotspots that can burn food while ensuring that the meal is cooked uniformly. The same principle is applied in other kitchen appliances, such as toasters and grills, where the design maximizes conductive heat transfer to achieve optimal cooking results.

In the realm of technology, conduction is instrumental in managing heat in electronics. Devices such as laptops and smartphones generate heat during operation, and effective heat dissipation is crucial for their performance and longevity. Heat sinks, often made from materials like aluminum, are designed to draw heat away from the processor by maximizing surface area and facilitating conduction. When thermal interface materials are applied between the heat-generating components and the heat sink, they enhance conduction further, ensuring that devices operate within safe temperature ranges.

Overall, the applications of conduction extend to many fields, including automotive engineering, HVAC systems, and even renewable energy technologies. For example, in solar thermal collectors, conduction is utilized to transfer heat from solar panels to water, providing efficient heating solutions for residential and industrial uses. Recognizing the role of conduction not only helps us appreciate the technologies we use daily but also highlights opportunities for innovation and improvement in energy efficiency across various sectors.

Measuring Heat Transfer: Tools and Techniques

Measuring heat transfer accurately is essential for optimizing processes in cooking, manufacturing, and electronics. Numerous tools and techniques allow us to quantify conduction, ensuring that systems function efficiently and safely. Understanding these methodologies not only aids in scientific experimentation but also supports engineering designs that prioritize thermal management.

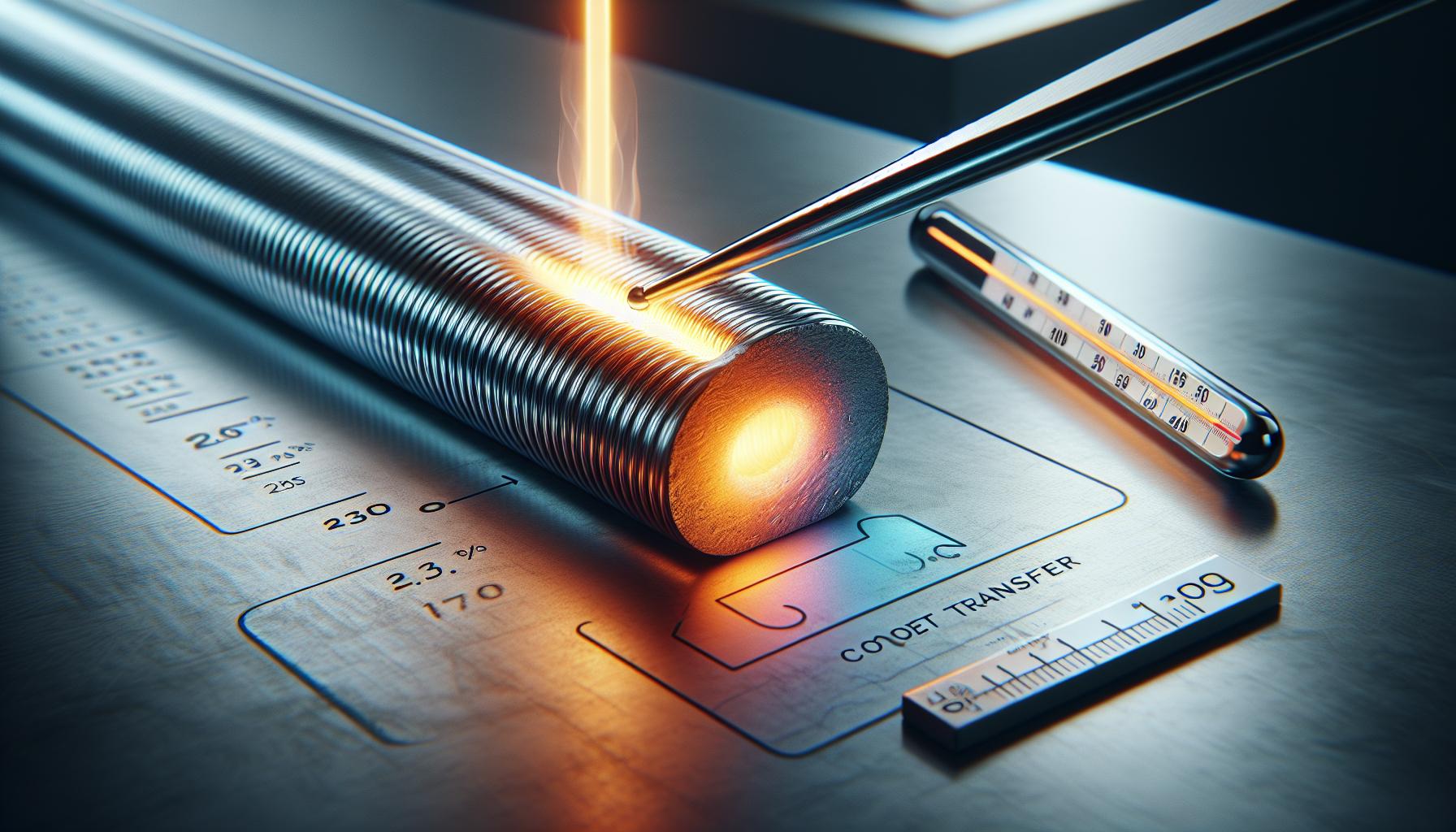

One of the most straightforward methods to measure heat transfer through conduction is using a thermal conductivity meter. This device assesses the ability of a material to conduct heat by evaluating the temperature differential between its ends. The guarded hot plate method is another robust technique, often employed for fabricating and characterizing insulating materials. In this approach, a heated plate transfers energy through the test material to a cold plate, and the heat flow is quantified based on the temperature gradient established across the material.

In many practical applications, thermocouples have become the go-to instruments for measuring temperature changes in materials. By placing thermocouples at strategic locations within an experimental setup, it’s possible to monitor how heat propagates. Embedded in devices, these sensors provide real-time feedback, crucial in environments where overheating could compromise functionality. Moreover, there are Infrared thermometers available that can measure surface temperatures without contact, which is particularly useful in situations where traditional methods cannot be applied directly.

Lastly, computational methods, such as Finite Element Analysis (FEA), are employed extensively in research and product development. By creating a digital model of the thermal environment, designers can simulate heat distribution and identify potential hot spots before physical prototypes are built. This method not only saves time and resources but also leads to more innovative designs tailored to efficient heat transfer.

By employing a combination of these tools and techniques, scientists and engineers can effectively measure and manage heat transfer through conduction, enabling advancements across various fields and enhancing our daily technologies.

Improving Heat Transfer in Engineering and Design

To enhance heat transfer through direct contact, engineers and designers can employ several strategic methods that leverage material properties, surface treatments, and innovative design techniques. The effectiveness of heat transfer depends significantly on the thermal conductivity of the materials used and the surface area available for heat exchange. Materials with high thermal conductivity, like copper or aluminum, are often preferred in applications where efficient heat transfer is critical. Understanding these materials’ properties helps in selecting components that maximize heat conduction in various systems, from electronics to cooking equipment.

Furthermore, optimizing contact surfaces can significantly improve heat transfer. By increasing the surface area through designs such as fins or heat sinks, engineers provide more opportunity for heat to be conducted away from hot spots. Surface roughness can also play an important role; textured surfaces can enhance the interactions at the microscopic level, which can increase the efficacy of thermal conduction. For instance, in thermal interface materials (TIMs), using substances like thermal grease or pads can fill microscopic gaps between surfaces, boosting thermal connectivity and efficiency.

Active Heat Transfer Techniques

In addition to passive design enhancements, active heat transfer techniques can dynamically manage heat. Utilizing fans or pumps to manipulate air or liquid flow around components not only disperses heat more effectively but also allows for targeted cooling. For example, liquid cooling systems in high-performance computing harness the high thermal capacity of liquids to transfer heat away from critical areas much more efficiently than air alone.

Employing simulation software, such as Computational Fluid Dynamics (CFD), can provide invaluable insights during the design phase. Engineers can model heat flow patterns within a system and identify potential hotspots before physical assembly, allowing for adjustments that can optimize heat transfer prior to manufacturing. This proactive approach minimizes costly iterations and enables the creation of more efficient and robust designs.

In conclusion, enhancing heat transfer through direct contact involves a combination of selecting the right materials, optimizing surfaces, and using both passive and active methods. By understanding the principles and leveraging innovative technologies, engineers can significantly improve the efficiency and performance of thermal management systems across various applications.

Common Myths About Heat Transfer Debunked

Heat transfer, especially through direct contact, is often surrounded by misconceptions that can hinder understanding and application. One prevalent myth is that all materials conduct heat equally well. In reality, thermal conductivity varies significantly between materials. For example, metals like copper and aluminum are exceptional conductors, while wood or air are relatively poor. This variance is crucial for engineers and designers when selecting materials for applications requiring efficient heat transfer. Understanding these differences allows for optimized thermal management systems, such as using copper in heat sinks or aluminum in cookware.

Another common misconception is that larger contact areas always lead to better heat transfer. While increasing the surface area can enhance heat conduction, the effectiveness is contingent on the surface quality and the materials in contact. Textured or rough surfaces can promote better heat transfer by increasing the microscopic interactions between them. Conversely, if the surfaces are not flat or clean, the actual contact area may be significantly reduced, which can hinder efficiency. Innovations such as thermal interface materials (TIMs) are designed to fill the gaps between surfaces, improving contact and thus conduction.

Additionally, many believe that heat transfer can occur only between solid objects. While it’s true that solid-to-solid conduction is a primary form of heat transfer through direct contact, substances like liquids and even gases can play a role in indirect ways. For instance, in composite materials where metals are bonded with polymers, heat can transfer across phases, leveraging the properties of both solid and liquid states, particularly at higher temperatures where the behavior of materials changes.

Finally, there’s a misconception that once heat is transferred, it disappears or is lost. In reality, heat transfer is a dynamic process; energy is conserved and can be transferred, transformed, or stored. This principle is critical for numerous applications-from energy-efficient home designs that capture and redistribute heat to advanced materials that can store thermal energy for later use. Recognizing these dynamics is essential for developing technologies that enhance energy efficiency and performance in various systems.

In summary, debunking these myths empowers engineers, students, and makers to embrace a more nuanced understanding of heat transfer through direct contact. Mastering these truths is not just academic; it translates into real-world applications that enhance efficiency and innovation in thermal management across industries.

Future Trends in Heat Transfer Research and Innovation

Advancements in heat transfer technology are poised to reshape industries, enabling more efficient thermal management systems that are critical for energy conservation and performance enhancement. Recent research is focusing on the development of nano-materials and advanced composites that demonstrate superior thermal conductivity compared to traditional materials. For instance, integrating carbon nanotubes or graphene into polymers can significantly improve their ability to conduct heat, making them ideal for applications in electronics, aerospace, and automotive sectors. This shift towards using high-performance materials not only enhances heat transfer capabilities but also reduces the weight and size of devices, leading to more compact and energy-efficient designs.

Emerging technologies like Additive Manufacturing (3D printing) are also revolutionizing the landscape of heat transfer design. This innovative method allows for the creation of complex geometries that can optimize contact areas and flow paths for heat dissipation. Engineers can design custom heat sinks or cooling channels tailored for specific applications, maximizing conduction efficiency where it is most needed. Moreover, the ability to produce these components on-demand reduces material waste and allows for rapid prototyping, speeding up the innovation cycle in product development.

Smart Thermal Management Systems

The integration of IoT (Internet of Things) technology is another exciting trend in heat transfer research. Smart sensors can monitor and control thermal conditions in real time, adjusting cooling strategies based on current needs rather than fixed schedules. This capability leads to significant energy savings in buildings, vehicles, and industrial processes. By leveraging data analytics, these systems can predict when heat dissipation is necessary, optimizing thermal performance without human intervention. This trend is already being utilized in data centers, where managing heat efficiently is crucial for maintaining performance and reliability.

As we look forward, the potential for biomimicry in heat transfer technology offers fascinating possibilities. Nature has perfected heat transfer systems over millions of years; for example, the structure of polar bear fur minimizes heat loss while maximizing warmth. Researchers are studying these natural systems to inspire new materials and technologies that can manage heat in more effective and energy-efficient ways. By mimicking these biological processes, engineers can design innovative solutions that not only improve heat transfer but also reduce environmental impacts.

As these trends continue to evolve, they hold the promise of enhancing energy efficiency, minimizing waste, and advancing heat transfer technologies that meet the demands of a rapidly changing world.

Frequently Asked Questions

Q: What is the fundamental process of heat transfer by direct contact called?

A: The transfer of heat through direct contact is known as conduction. This process occurs when heat energy is transferred between materials that are in direct physical contact, facilitating energy flow from warmer regions to cooler ones.

Q: How does conduction differ from convection and radiation in heat transfer?

A: Conduction transfers heat through direct contact, whereas convection involves the movement of fluids (liquids or gases) and radiation transfers heat through electromagnetic waves. Understanding these differences is crucial in applications of thermal dynamics.

Q: What are common examples of conduction in everyday life?

A: Common examples of conduction include cooking on a stovetop, where heat moves from the burner to the pot, and touching a hot metal object, where heat transfers directly from the object to your skin.

Q: What factors influence the efficiency of heat transfer through conduction?

A: The efficiency of heat transfer by conduction is influenced by material properties (thermal conductivity), the temperature difference between materials, and the contact area. Enhancing these factors can lead to more effective thermal management in engineering applications.

Q: Why is conduction important in the context of thermal management?

A: Conduction plays a critical role in thermal management as it ensures efficient heat dissipation in systems like electronics. Proper conduction prevents overheating and maintains performance by directing heat away from sensitive components.

Q: How can conduction be improved in engineering designs?

A: Engineers can improve conduction by using materials with high thermal conductivity, increasing surface contact area, and optimizing component design to ensure effective thermal pathways. These strategies enhance system reliability and efficiency.

Q: What tools are used to measure heat transfer via conduction?

A: Tools such as thermocouples, thermal cameras, and heat flux meters are commonly used to measure heat transfer through conduction. These instruments help in analyzing thermal performance and identifying hotspots in various applications.

Q: What are some myths about conduction heat transfer?

A: One common myth is that all materials conduct heat equally; however, materials differ greatly in thermal conductivity. Understanding this can prevent inefficiencies in designs and improve energy conservation efforts.

In Summary

Understanding the transfer of heat through direct contact, known as conduction, is essential for various applications in science and engineering. By grasping this principle, you can enhance your projects, whether that’s improving thermal efficiency in your designs or seeking effective heat management solutions. Don’t let this knowledge slip away-explore our related articles on thermal conductivity and heat transfer methods to deepen your understanding and apply these concepts practically.

If you have further questions about conduction or its applications, we’d love to hear from you in the comments below! For ongoing insights, consider signing up for our newsletter, where we share expert tips and the latest resources on thermal dynamics. Remember, mastering these concepts is just the beginning-continue your journey through our site to unlock more valuable information that can elevate your expertise.