Have you ever noticed how some materials can keep you warm in winter while others conduct electricity like it’s second nature? This property comes from substances that do not readily transfer heat or electricity, known as insulators. These materials are vital in our everyday lives, from ensuring our homes stay energy-efficient to protecting us from electrical hazards. Understanding insulators not only helps us make informed decisions about materials in construction and electronics but also drives innovation in developing better energy solutions. Join us as we explore the fascinating world of insulators, their applications, and how they can enhance efficiency while safeguarding against risks. Whether you’re a student, researcher, or just curious about the science around you, this journey promises to uncover the essential roles insulators play in our modern lives.

What Are Insulators and Their Role?

Insulators play a crucial role in our daily lives by preventing the unnecessary transfer of heat and electricity. These materials, often overlooked, serve as barriers that keep energy contained, ensuring optimal functionality in various applications. At their core, insulators are substances with low thermal and electrical conductivity. This means they do not readily allow heat or electrical current to pass through, which is vital for energy efficiency and safety. For instance, when you touch a metal handle in the sun, the metal rapidly conducts heat, making it hot to the touch. In contrast, a plastic handle would remain cool, illustrating the effective insulating properties of the latter.

Types of Insulators and Their Applications

There are several types of insulating materials, each designed to meet specific needs. Common insulators include:

- Thermal Insulators: These materials, such as fiberglass and foam, help maintain desired temperatures in buildings and appliances by reducing heat flow. For example, insulation in homes keeps interiors warm during winter and cool in summer.

- Electrical Insulators: Rubber, glass, and ceramics are typical electrical insulators that prevent the flow of electricity, protecting both equipment and human safety. Wires coated with these materials ensure that electrical currents are contained within the conduits, reducing the risk of shocks or shorts.

- Acoustic Insulators: Materials like soundproofing foam and mass-loaded vinyl limit sound transmission in buildings, enhancing comfort in residential and commercial environments.

Why Insulation Matters

The importance of insulation extends beyond just energy savings; it significantly impacts safety, comfort, and environmental sustainability. For instance, effective thermal insulation can decrease the demand for heating and cooling systems, leading to lower energy bills and reduced greenhouse gas emissions. Additionally, in electrical applications, correct insulation protects users from dangerous voltages while minimizing energy loss during transmission. With advancements in technology, the development of more effective and sustainable insulating materials continues to evolve, offering solutions that further integrate energy efficiency with everyday use.

Understanding insulators allows us to appreciate their impact on safety and efficiency in both industrial and domestic contexts. By effectively managing heat and electricity flow, these materials contribute significantly to the sustainability and comfort of modern living.

Properties of Thermal and Electrical Insulators

The effectiveness of materials as insulators hinges on their inherent properties, making them key players in managing heat and electricity flow. At a fundamental level, thermal and electrical insulators possess low thermal and electrical conductivity, which indicates their ability to resist the transfer of heat and electrical currents. This resistance is typically characterized by high specific heat capacity for thermal insulators and a small number of free electrons in the case of electrical insulators. As a result, these materials help maintain energy efficiency and safety in various applications.

One significant property of thermal insulators is their ability to minimize heat transfer. Materials like fiberglass and expanded polystyrene are excellent examples, as their structure is designed to trap air pockets, which slows the movement of heat. This is particularly beneficial in construction, where proper insulation ensures that homes remain warm during winter and cool in summer. In contrast, electrical insulators such as rubber and ceramics are designed to impede the flow of electric current, protecting against electrical hazards and preventing equipment damage. This property is vital not only in consumer electronics but also in high-voltage machinery, where insulation prevents dangerous shocks and short circuits.

Insulators also exhibit important behavioral characteristics under different environmental conditions. For instance, many insulating materials perform optimally within a specific temperature range. As temperature increases, some thermal insulators may lose their effectiveness due to material degradation or phase changes. Similarly, the insulation properties of electrical materials can be affected by humidity and temperature fluctuations, highlighting the need for careful selection based on application requirements. Understanding these nuances enables engineers and builders to choose the right materials, ensuring that both thermal and electrical systems operate efficiently and safely.

Ultimately, the core are integral to modern design and engineering. Combining their unique characteristics with advancements in material science continues to unlock new applications, from sustainable home construction to high-tech electronics, where the balance between energy efficiency and safety is increasingly essential.

Types of Insulating Materials Explained

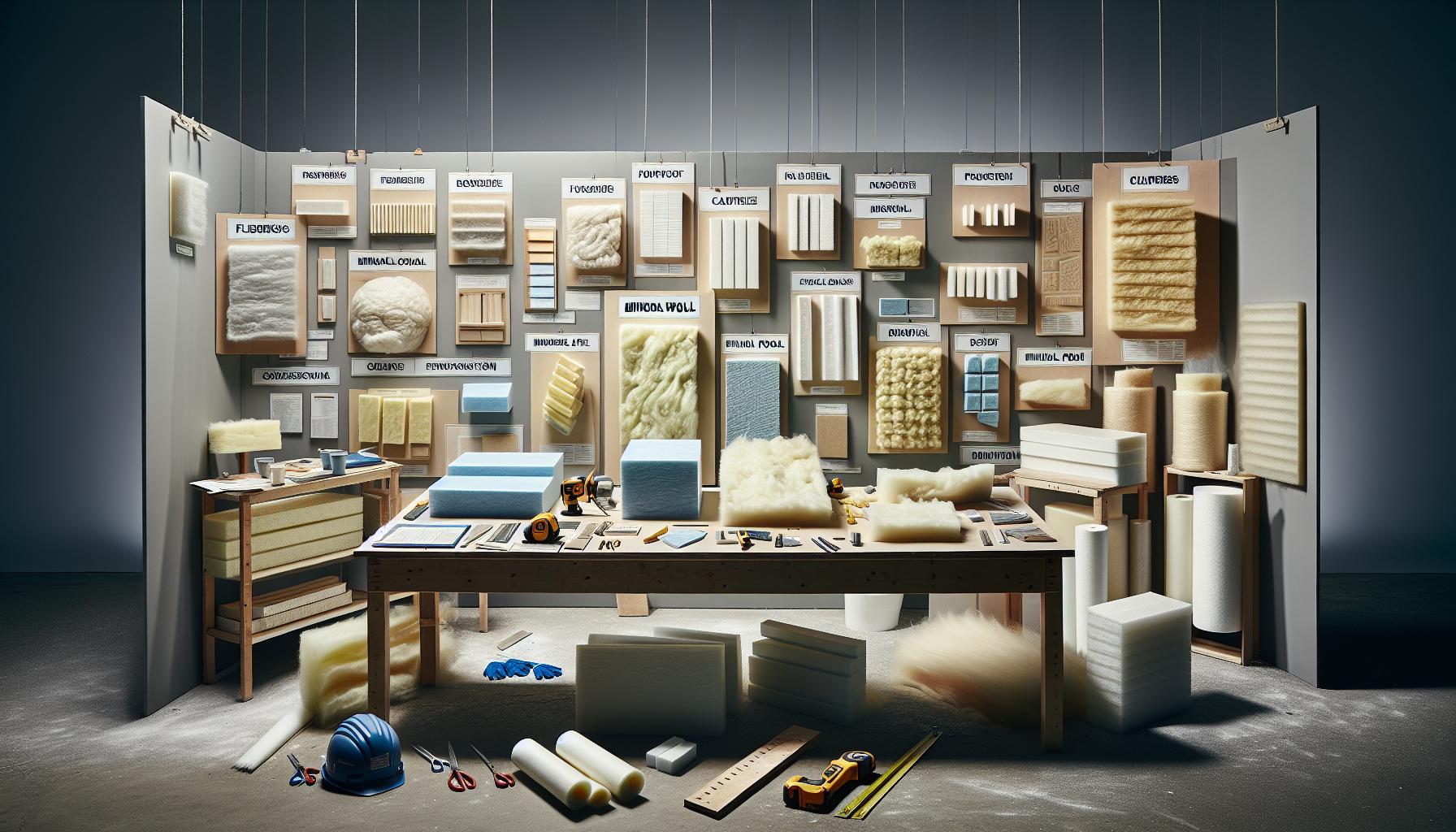

Insulating materials are crucial in many applications, from building construction to electronics, as they resist the transfer of heat and electricity. Understanding the various types of insulating materials helps in selecting the right one for specific needs, ensuring optimal performance and efficiency. The main categories of insulators can be classified based on their thermal and electrical properties.

Common Thermal Insulators

Thermal insulators work primarily by minimizing heat transfer. Materials like fiberglass, expanded polystyrene (EPS), and polyurethane foam are popular choices due to their excellent ability to trap air, which slows down heat movement. For instance, fiberglass batts are widely used in residential insulation, providing a effective barrier against cold winters and hot summers. Mineral wool, another effective thermal insulator, combines high resistance to heat with fireproof qualities, making it suitable for industrial applications as well as residential use.

Key Examples of Thermal Insulators:

- Fiberglass: Lightweight, cost-effective, and non-combustible, ideal for ceilings, walls, and floors.

- Expanded Polystyrene (EPS): Rigid foam used in insulation panels, known for its moisture resistance.

- Cellulose: Made from recycled paper, cellulose is an eco-friendly choice that also provides sound insulation.

Electrical Insulators

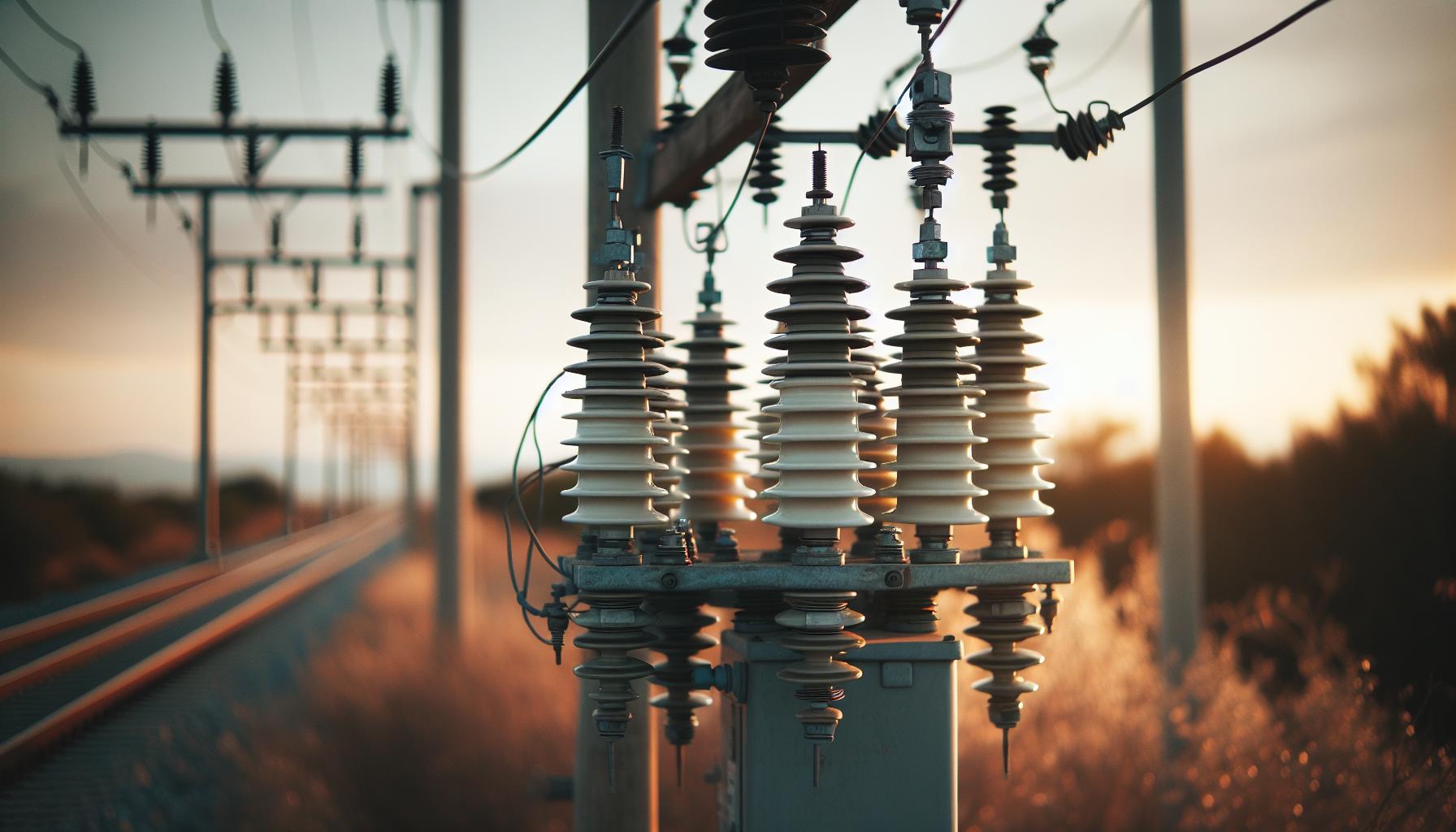

Electrical insulators, on the other hand, are designed to obstruct the flow of electric current. Materials such as rubber, ceramics, and glass have a high dielectric strength, meaning they can withstand high voltages without conducting electricity. This property is essential in preventing electrical hazards and ensuring the safety of electronic components. For example, rubber insulators are commonly used in power cables and electrical connectors, while ceramic insulators are often employed in high-voltage power lines due to their excellent temperature resistance and durability.

Characteristics of Electrical Insulators:

- Rubber: Flexible and adaptable, providing a high level of protection against electric shock.

- Ceramics: Rigid, heat-resistant, and effective in outdoor applications where weather resistance is necessary.

- Glass: Offers excellent insulating properties and is often used in electrical circuits.

Choosing the right insulating material involves understanding the thermal and electrical requirements of the application, as well as environmental factors such as temperature and humidity. Not only do these materials play a critical role in energy efficiency, they also enhance safety by reducing the risk of heat loss and electrical hazards. With continuous advancements in material science, new and innovative insulators are being developed, pushing the boundaries of what is possible in energy efficiency and safety.

Understanding Thermal Conductivity vs. Electrical Conductivity

Understanding the distinction between thermal and electrical conductivity is crucial when selecting insulating materials for various applications. While both properties relate to how materials transfer energy, they operate in different contexts. Essentially, thermal conductivity refers to a material’s ability to transfer heat, whereas electrical conductivity pertains to its capacity to conduct electricity. This understanding key helps engineers and builders choose the right materials for thermal insulation and electrical safety.

Thermal conductivity is measured in watts per meter-kelvin (W/m·K) and dictates how well a material can conduct heat. Lower thermal conductivity values indicate better insulating properties, which is essential for applications such as building insulation and thermal shields. For instance, materials like fiberglass and polystyrene are selected for their low thermal conductivity, which makes them ideal for minimizing heat loss in buildings. On the other hand, materials with high thermal conductivity, such as metals, are often used in applications where heat transfer is desired, like in heat sinks or cooking utensils.

Electrical conductivity, measured in siemens per meter (S/m), defines how effectively a material allows the flow of electric current. Insulating materials, such as rubber and ceramics, exhibit low electrical conductivity to prevent electrical leakage, ensuring safety in wiring and electronic devices. Understanding the environment’s requirements-like whether it will face high voltages or extreme temperatures-can guide the selection of appropriate insulation materials to enhance both safety and efficiency. Notably, some materials can serve dual purposes; for example, certain ceramics exhibit both thermal resistance and electrical insulating properties, making them versatile choices in engineering applications.

In practical settings, the balance between thermal and electrical conductivity is essential. Industry professionals must assess both properties, as high thermal insulation without electrical safety could lead to hazards, particularly in electrical components. Thus, a comprehensive understanding of these properties not only informs material selection but also supports innovation in insulation technologies, driving advancements in energy efficiency and safety across various fields.

Applications of Insulating Substances in Real Life

Insulating materials play a pivotal role in our daily lives, often without us even realizing it. From the walls of our homes to the cables that power our electronics, insulators are everywhere, ensuring safety and efficiency in countless applications. By preventing the transfer of heat and electricity, these substances help maintain comfortable temperatures, reduce energy costs, and protect against electrical hazards. Here’s a closer look at how these materials are utilized in various fields, enhancing both safety and performance.

In residential and commercial buildings, insulation like fiberglass and foam board is crucial for energy efficiency. These materials reduce heat loss in winter and keep interiors cool during summer, thereby minimizing the need for excessive heating and cooling. For instance, well-insulated walls can lead to a 30% reduction in energy bills, making them not only an eco-friendly choice but also a financially wise one. Furthermore, insulation also contributes to soundproofing, helping to create quieter environments and ensuring privacy between rooms.

Another significant application is in the electrical industry, where insulating materials are vital for the safety of electrical components. Materials such as PVC (polyvinyl chloride) and rubber are commonly used in wiring insulation to prevent short circuits and electrical fires. For example, the insulation around power cables not only protects users from electric shock but also maintains the integrity of the electrical signal transmitted through the wires. In high-voltage power lines, specialized ceramic insulators are utilized to support conductors while preventing electricity from leaking into the environment.

Transport and Aerospace Applications

In the transport sector, insulating materials are indispensable in vehicles, where they help reduce noise and improve thermal comfort. Automotive manufacturers use sound-deadening materials and thermal insulation to enhance the driving experience by keeping the cabin quieter and more comfortable. Similarly, in aerospace applications, lightweight insulating materials are crucial for maintaining temperature control and ensuring the safety of electronic instruments in aircraft. They help manage heat generated during flight and protect sensitive components from extreme temperatures.

In summary, the applications of insulating substances extend far beyond conventional uses, integrating seamlessly into various aspects of modern life-from providing thermal comfort and energy efficiency in buildings to ensuring safety in electrical systems and enhancing performance in transport and aerospace industries. As technology advances, the development of new insulating materials continues to expand their role, promising even more innovative applications in the future. By understanding and utilizing these materials effectively, we can maximize their benefits in everyday situations.

The Science Behind Heat and Electricity Transfer

When we talk about materials that don’t readily transfer heat or electricity, we delve into the fascinating world of insulators. These substances showcase unique properties that prevent or significantly slow down the transfer of thermal energy and electrical current. Understanding these principles is crucial for optimizing energy efficiency in our homes and ensuring safety in electrical applications.

At the core of this discussion lies the concept of conductivity. Thermal conductivity measures how well a material can conduct heat, typically quantified in Watts per meter-kelvin (W/m·K). In contrast, electrical conductivity gauges a material’s ability to conduct electricity, measured in siemens per meter (S/m). Insulators exhibit low thermal and electrical conductivity, meaning that they resist energy transfer effectively. For example, materials like fiberglass, expanded polystyrene, and ceramic exhibit poor conductivity, making them excellent choices for both construction and electrical applications.

These materials achieve their insulative properties through their atomic and molecular structures. Insulators tend to have a high density of bonds that hold electrons tightly, reducing their mobility. This tight binding means that when heat energy is introduced, the energy cannot easily travel through the material, reflecting its low thermal conductivity. In practical terms, this is why a person can touch a well-insulated water pipe without feeling the intense heat of the water inside.

Similarly, the structural characteristics of insulators inhibit the flow of electrical charges. Common insulating materials such as rubber and PVC have a non-metallic atomic structure that lacks free electrons, which are necessary for electrical conductivity. Consequently, these materials encapsulate wires and cables, creating barriers that prevent hazardous surges of electricity from escaping-which is critical for domestic safety and operational efficiency in electrical infrastructure.

Understanding the mechanisms behind heat and electricity transfer equips us with the knowledge to select the appropriate insulating materials for various applications, enhancing energy efficiency and safety across the board. Adopting technologies and materials that harness these principles truly empowers us to optimize our environmental impact while ensuring functionality in our homes and industries.

Comparative Analysis of Common Insulators

The world of insulators is rich with diversity, showcasing materials that excel at preventing the transfer of heat and electricity. This comparative analysis delves into the characteristics and applications of several common insulating materials, enabling a better understanding of their unique properties and ideal uses.

Among the most prevalent thermal insulators is expanded polystyrene (EPS), often seen in construction and packaging. With a thermal conductivity ranging from 0.035 to 0.045 W/m·K, EPS is lightweight and affordable, making it ideal for insulation in walls, roofs, and floors. Its closed-cell structure traps air, substantially slowing heat transfer, which helps maintain energy efficiency in buildings.

Fiberglass is another widely used insulation material, particularly in residential settings. Its thermal properties are comparable to those of EPS, with thermal conductivity similar to or slightly better than EPS. Fiberglass insulation is available in batts, rolls, or loose-fill forms. The glass fibers trap air, providing excellent thermal resistance, and it is often used in attics and behind walls. However, handling fiberglass requires caution, as the fine fibers can irritate the skin and respiratory system.

When it comes to electrical insulation, rubber and polyvinyl chloride (PVC) are the frontrunners. Rubber insulation is notable for its elasticity and resistance to moisture, making it suitable for use in outdoor electrical applications. PVC, on the other hand, is commonly used to insulate wires and cables in homes and industrial settings due to its durability and resistance to fire and chemicals. Both materials offer low electrical conductivity, ensuring safety in electrical installations.

Ceramic materials also play a crucial role, particularly in high-temperature applications. With thermal conductivities varying greatly depending on their composition, ceramics can function as effective insulators when used in electrical applications, such as insulators for power lines and in high-temperature furnaces. Their ability to withstand high temperatures without degrading makes them invaluable in specific industrial contexts.

Overall, the selection of an insulator should be guided by the specific application, considering factors like thermal and electrical conductivity, environmental conditions, and safety requirements. Each insulating material brings its own strengths and ideal use cases, influencing both performance and efficiency across a range of applications.

Impact of Temperature on Insulation Efficiency

Temperature plays a crucial role in determining the efficiency of insulation materials, affecting their ability to prevent the transfer of heat and electricity. As the temperature around an insulating material fluctuates, its thermal and electrical properties can change significantly, potentially diminishing its effectiveness. For example, most insulating materials perform optimally within a specific temperature range. When temperatures exceed or drop below this range, the structure and composition of the materials can alter, leading to increased thermal conductivity or, in the case of electrical insulators, potentially allowing unwanted electrical flow.

The performance of thermal insulators, such as expanded polystyrene (EPS) and fiberglass, is particularly sensitive to temperature variations. As temperatures rise, the gases trapped within these materials may become more energetic, leading to higher rates of thermal transfer. In contrast, extreme cold can lead to moisture accumulation and eventual freezing, which may compromise the material’s structure and insulating capabilities. For residential applications, understanding these temperature impacts can guide homeowners in selecting appropriate insulation materials suitable for their specific climate conditions.

Real-World Applications and Considerations

In practical scenarios, consider the insulation used in attics or walls in different seasons. In winter, when the external temperature drops significantly, insulation must maintain a barrier to prevent heat loss. If the material’s efficiency declines due to the intense cold, this could lead to higher heating costs and uncomfortable living conditions. Conversely, in summer, insulation must also prevent heat from penetrating the home. Here, the insulation’s capacity to resist heat transfer becomes vital, underscoring the importance of selecting materials that retain effectiveness across different temperatures.

- Choosing the Right Insulation: Opt for materials that provide consistent performance over the expected temperature range in your area.

- Monitoring Insulation Conditions: Regularly check insulation, especially in extreme climates, to ensure it hasn’t degraded due to temperature effects.

- Using Appropriate Installation Techniques: Proper installation can enhance the thermal resistance of insulation, allowing it to perform better under temperature variations.

Understanding how temperature influences insulation efficiency allows builders and homeowners to make informed choices about materials and installation. Insights into these dynamics can significantly enhance energy conservation efforts and overall comfort in living spaces, paving the way for more sustainable building practices.

Innovations in Insulation Technology

The field of insulation technology is experiencing a rapid transformation, thanks to innovations that enhance the efficiency and effectiveness of materials. New advancements are making it possible to develop substances that not only reduce heat transfer but also withstand diverse environmental challenges. For instance, aerogel, often referred to as “frozen smoke,” is one of the most effective insulators available today. Its structure allows for extremely low thermal conductivity, making it an ideal solution for a variety of applications-from building insulation to space exploration.

Another exciting development is the introduction of phase change materials (PCMs). These materials absorb, store, and release thermal energy during the process of melting and freezing. When incorporated into walls or ceilings, PCMs can help regulate indoor temperatures, minimizing the need for additional heating or cooling. This innovation holds significant potential for reducing energy consumption in both residential and commercial buildings, promoting a more sustainable approach to energy use.

Moreover, smart insulation technologies are emerging, which integrate sensors and advanced materials to monitor and adjust their performance in real time. For example, some systems can adapt to humidity changes, improving the overall comfort of a space while maintaining energy efficiency. This adaptability is crucial in regions with fluctuating climates and can greatly enhance the longevity of building structures by preventing issues related to moisture and temperature extremes.

As these innovations continue to evolve, builders, architects, and homeowners must stay informed about the latest materials and technologies available. This knowledge not only aids in making more informed choices when selecting insulation but also contributes to broader efforts in energy conservation and sustainability in construction. By embracing these advancements, we can create environments that are not only comfortable but also more resilient against the challenges posed by climate change.

Challenges and Limitations of Insulating Materials

Insulating materials play a crucial role in energy conservation, but they are not without their challenges and limitations. A notable issue is performance variability based on environmental conditions. For instance, insulation efficiency can diminish in extreme temperatures-both hot and cold. This results in increased energy usage to maintain comfortable indoor conditions, thereby offsetting the benefits of the insulation itself. Additionally, moisture can significantly impact the performance of many insulating materials. When insulation becomes wet, its thermal resistance typically decreases, leading to higher energy costs and potential growth of mold and mildew.

Another significant challenge is the cost vs. effectiveness equation. While some of the most effective insulating materials, such as aerogels and vacuum insulation panels, offer exceptional thermal resistance, they can be prohibitively expensive for widespread use. In contrast, more affordable materials may not perform as well, leaving homeowners and builders to weigh the long-term savings against the upfront costs. This is especially pertinent in regions with strict building codes that require stringent energy performance ratings, forcing builders to reconsider their choices.

Durability and lifespan also present hurdles. Many insulating materials degrade over time due to UV exposure, temperature fluctuations, or physical wear and tear. This degradation can lead to reduced insulating effectiveness, necessitating replacement more frequently than anticipated. For instance, traditional foam insulations can deteriorate, losing their R-value and requiring costly replacements and repairs.

Finally, there’s the environmental impact of manufacturing and disposing of insulation materials that can’t be overlooked. Although many companies are adopting greener practices, the production of some insulation types-especially those made from synthetic materials-can involve harmful chemicals that negatively impact the environment. Sustainable options like cellulose or sheep’s wool are available, but they may lack the same performance metrics as their synthetic counterparts, creating a dilemma for eco-conscious builders.

These challenges illustrate that while insulating materials can be highly effective in reducing energy transfer, they come with caveats that demand careful consideration in both selection and application.

Future Trends in Insulative Solutions

Innovative approaches to insulation are transforming how we manage heat and electricity transfer in buildings, appliances, and electronics. As climate change drives a heightened demand for energy efficiency, will focus on advanced materials and smart technologies that enhance thermal and electrical insulation without compromising usability or sustainability.

One notable trend is the integration of smart insulation materials that respond to their environments. These materials can dynamically adjust their properties based on temperature and humidity, effectively optimizing energy use. For example, phase change materials (PCMs) can absorb and release thermal energy, maintaining comfortable indoor temperatures with less reliance on heating and cooling systems. This technology not only promises energy savings but also improves indoor air quality by reducing reliance on mechanical ventilation.

Additionally, biodegradable and sustainable insulating materials are gaining traction. As concerns about the environmental footprint of traditional insulation grow, developers are turning to natural fibers like hemp, cellulose, and even mycelium, a form of fungus. These materials offer excellent insulating properties while being less harmful to the environment. For instance, mycelium-based insulation is not only sustainable but also has good thermal performance, providing a viable alternative to petrochemical-derived products. These innovations reflect a broader industry shift toward environmentally responsible practices.

Finally, advancements in nano-insulation technologies are paving the way for next-generation insulation solutions. By manipulating materials at the nanoscale, researchers are developing products that offer superior thermal barriers with reduced thickness and weight. Aerogels, for instance, are already a prime example of this technology, providing exceptional insulation properties while remaining lightweight and versatile. Furthermore, as manufacturing processes improve, the cost of these advanced materials is expected to decrease, making them more accessible for widespread application in residential and commercial projects.

These trends signal a future where insulation not only conserves energy but also enhances sustainability and adaptability in our built environments. As these technologies become more integrated, we can expect a significant impact on energy consumption and environmental stewardship, fundamentally altering how we consider insulation in design and construction.

Faq

Q: What is an insulator?

A: An insulator is a material that does not readily transfer heat or electricity. These substances are essential in preventing the loss of thermal energy or electrical current, making them crucial in various applications such as building insulation and electrical wiring.

Q: How do insulators work?

A: Insulators function by having tightly bound electrons that can’t move freely. This structure limits energy transfer, whether in the form of heat or electrical currents. For effective insulation, materials must be low in thermal conductivity and resistive to electrical flow.

Q: What are common insulating materials?

A: Common insulative materials include rubber, glass, foam, and ceramic. Each material varies in effectiveness based on its application, such as thermal insulation in walls or electrical insulation in wires.

Q: Why are insulators important?

A: Insulators are vital because they enhance energy efficiency by reducing heat loss and preventing electrical mishaps. Their use in homes and appliances helps lower energy costs and improves safety.

Q: How can you test if a material is a good insulator?

A: To test if a material is a good insulator, measure its thermal or electrical conductivity. Low conductivity values indicate better insulative properties. You can also compare temperature changes in test environments to gauge effectiveness.

Q: What properties should an effective insulator have?

A: An effective insulator should possess low thermal and electrical conductivity, high resistance to energy transfer, and durability under various environmental conditions. These properties ensure longevity and reliability in applications.

Q: Can insulators become less effective over time?

A: Yes, insulators can become less effective due to wear, moisture absorption, or thermal degradation. Regular inspections and maintenance are essential to ensure they maintain their insulating properties.

Q: What is the difference between thermal and electrical insulators?

A: Thermal insulators resist heat transfer, while electrical insulators prevent the flow of electric current. Although some materials can act as both, their effectiveness in each role may vary based on their specific properties.

Insights and Conclusions

Thank you for exploring the fascinating world of substances that do not readily transfer heat or electricity. Understanding these materials is crucial in fields ranging from energy conservation to advanced technology applications. You now have the insights to consider how these insulating properties can enhance your projects or research.

Ready to dive deeper? Explore our articles on the latest innovations in thermal insulation materials and electrical insulators to see how these concepts apply in real-world scenarios. Don’t miss our resource hub for tools that can help you experiment and apply what you’ve learned!

Join our community by subscribing to our newsletter for updates and expert tips, and feel free to share your thoughts or questions in the comments below. Your engagement drives our commitment to bringing you valuable content that connects theory with practical application. Discover the potential of non-conductive materials today and take the next step in your knowledge journey!