Imagine interacting with technology in a way that feels almost seamless-a touch here, a swipe there, and your device responds instantly. This is the promise of Surface Acoustic Wave (SAW) technology, a key player in the field of touchscreens and sensors. By leveraging surface waves to detect and interpret user interactions, SAW enhances the efficiency and responsiveness of devices across various applications, from smartphones to industrial equipment. Understanding SAW technology not only satisfies curiosity about how modern devices operate but also highlights solutions for improving user experiences and functionality. As we delve deeper into this technology, you’ll discover its significant advantages, diverse applications, and the science that drives its innovation, making it an essential topic for anyone interested in the future of interactive technology.

Understanding Surface Acoustic Wave Technology

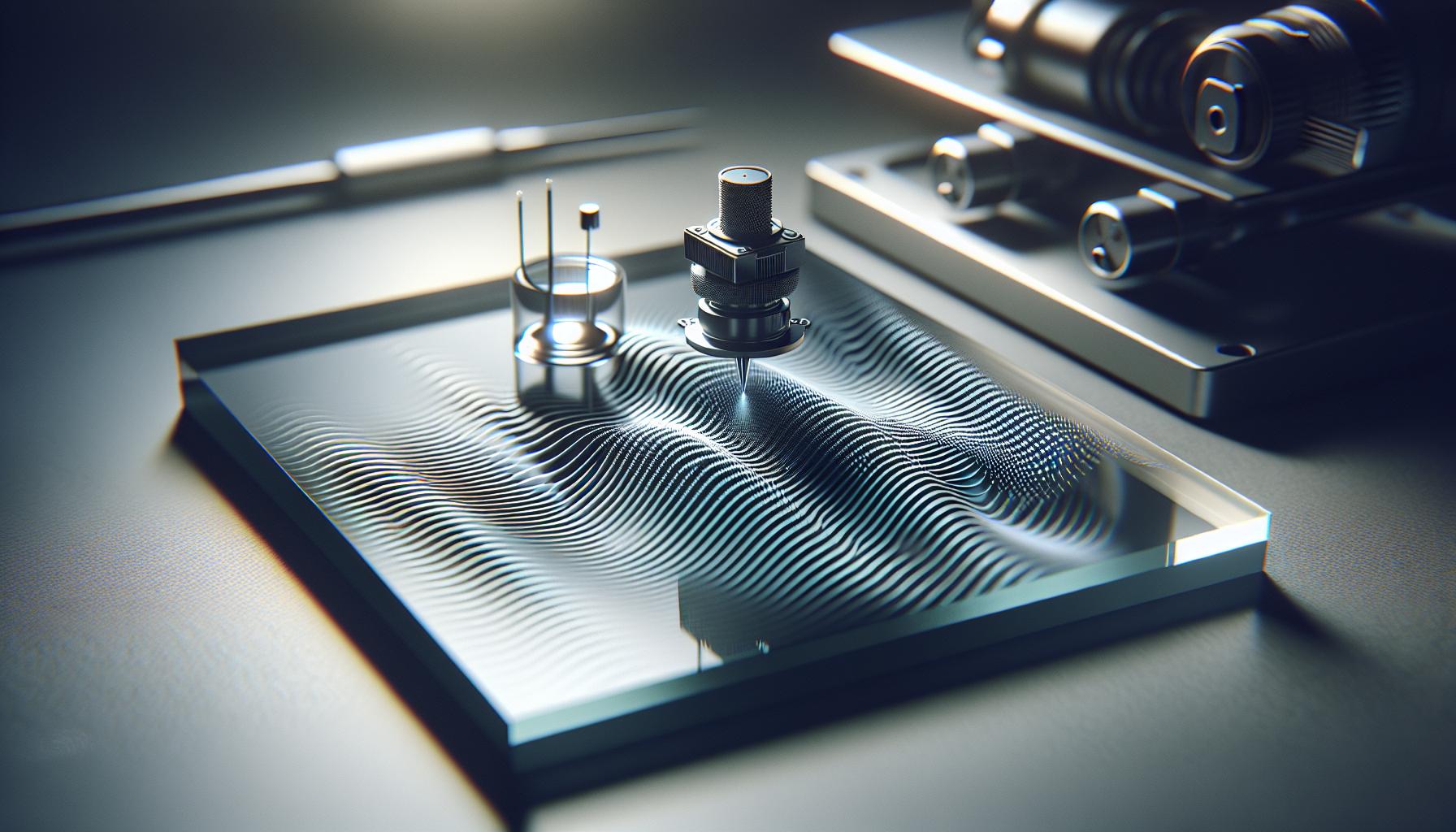

Surface Acoustic Wave (SAW) technology utilizes the unique properties of elastic waves that travel along the surface of a material, typically a piezoelectric substrate. When an electrical signal is applied, it creates mechanical waves that propagate across the surface. These waves can be manipulated to perform various tasks, making SAW devices versatile components in modern technology. For example, in communication systems, SAW filters enable the transmission and reception of specific frequencies while blocking unwanted signals, thereby enhancing signal quality and reducing interference.

This technology is fundamental in various applications, including telecommunications, automotive systems, and medical devices. In telecommunications, SAW filters are crucial for RF signal processing, where they help manage the spectral efficiency of wireless communications. In automotive technology, SAW sensors can monitor parameters such as temperature and pressure, providing critical data for vehicle performance. Additionally, in the medical field, SAW-based biosensors offer precise and rapid detection of biomolecules, paving the way for advancements in diagnostics.

Understanding SAW technology involves grasping key concepts such as wave propagation, the interplay between mechanical and electrical energy, and device architecture. SAW devices typically consist of interdigitated transducers (IDTs) that convert electrical signals into acoustic waves and vice versa. These components must be designed with precision to optimize performance, significantly affecting the device’s sensitivity and selectivity. Overall, the adaptability and efficiency of SAW technology position it as a vital player in the ongoing evolution of electronic and sensor technologies.

Key Applications of Surface Acoustic Wave Devices

Surface Acoustic Wave (SAW) devices are increasingly pivotal in various high-tech fields, thanks to their exceptional versatility and efficiency. These devices leverage the unique characteristics of acoustic waves that travel along the surface of piezoelectric materials. This ability to manipulate sound waves makes SAW technology crucial in applications ranging from telecommunications to environmental monitoring.

Telecommunications

In telecommunications, SAW filters play a vital role in RF signal processing. They allow precise frequency selection, enabling devices to distinguish between different signals and minimize interference. This capability is particularly important in mobile communications, where bandwidth is at a premium. For instance, SAW filters are commonplace in mobile phones, helping them to maintain clear calls and reliable data connections while filtering out noise.

Automotive Systems

Automotive technology also benefits significantly from SAW devices. Temperature and pressure sensors utilizing SAW technology offer increased accuracy and reliability compared to traditional sensors. These sensors can provide real-time data to onboard systems, enhancing performance and safety features. For example, SAW pressure sensors are used in tire pressure monitoring systems, alerting drivers to potential issues before they become critical.

Medical Devices

The medical field has also seen innovative applications of SAW technology, particularly in biosensors. SAW-based biosensors allow for quick and sensitive detection of biomolecules, crucial for diagnostics and disease monitoring. This rapid detection capability can facilitate timely medical interventions. Innovative applications include glucose monitoring for diabetic patients and pathogen detection in clinical samples, both of which illustrate the breadth of SAW applications in healthcare.

In summary, SAW devices are integral to advancing technology across multiple sectors due to their efficiency, accuracy, and effectiveness. As the demand for smaller, more precise devices increases, the role of Surface Acoustic Wave technology is expected to expand even further, making it a cornerstone in the evolution of modern electronics and sensor technologies.

Advantages of Surface Acoustic Wave Technology

Surface Acoustic Wave (SAW) technology offers a remarkable blend of precision and efficiency that is driving innovation across various industries. One of the standout advantages of SAW devices is their impressive sensitivity. Because they operate using mechanical vibrations that travel along the surface of piezoelectric materials, these devices can detect minute changes in mass, pressure, or temperature. This sensitivity makes SAW sensors particularly valuable in medical applications, such as glucose monitoring, where timely and accurate readings can be critical.

Another key benefit is their versatility. SAW technology is not limited to a single application; it can be tailored to fit diverse needs, ranging from telecommunications to automotive systems and environmental monitoring. For example, in telecommunications, SAW filters effectively manage radio frequency signals, enhancing performance by minimizing interference. This flexibility in application is paired with a compact design, allowing for integration into smaller devices without compromising functionality.

Robustness and Reliability

SAW devices are built to endure harsh environments, making them trusted choices in industrial applications. Their robust nature ensures consistent performance under varying temperatures and pressures, which is vital for systems that operate in challenging conditions, such as oil and gas exploration or aerospace. Additionally, the absence of moving parts minimizes wear and tear, leading to longer lifespans and reduced maintenance requirements.

The efficiency of SAW technology also contributes to lower energy consumption, a critical factor in an age where sustainability is paramount. Devices utilizing SAW sensors typically require less power than their traditional counterparts, offering an eco-friendly solution without sacrificing performance. This energy efficiency not only cuts operational costs but also aligns with global efforts toward reducing carbon footprints.

In summary, the -sensitivity, versatility, robustness, and energy efficiency-position it as a powerful tool across numerous applications. As industries continue to seek smarter and more efficient technologies, SAW devices are set to play an increasingly crucial role in shaping the future of sensors and signal processing.

Fundamental Principles of Surface Acoustic Waves

Surface Acoustic Wave (SAW) technology operates on fascinating principles that combine physics and engineering, enabling a wide range of applications from telecommunications to healthcare. At the core of SAW technology is the concept of mechanical waves traveling along the surface of a piezoelectric material. When an electrical signal is applied to such a material, it generates mechanical vibrations or acoustic waves that propagate along the surface. These waves can be manipulated and monitored, allowing SAW devices to detect various environmental parameters.

The piezoelectric effect is fundamental to SAW technology. Piezoelectric materials convert mechanical stress into electrical energy and vice versa. When an electric field is applied to these materials, they deform, creating surface waves. These waves can be generated and detected using interdigitated transducers (IDTs), which are tiny electrode structures designed to initiate and sense the propagation of these acoustic waves. As the wave travels, it can be affected by environmental changes, making it a sensitive means of detecting shifts in temperature, pressure, or mass.

Key Characteristics of Surface Acoustic Waves

Surface acoustic waves exhibit several unique characteristics that enhance their functionality. Firstly, they typically travel along the surface of the material, which means they are less influenced by bulk properties, allowing for higher sensitivity and precision in measurements. Secondly, the wavelength of SAW signals can be extremely small, on the order of micrometers, which enables the construction of compact devices that can be integrated into other technologies seamlessly.

For practical applications, SAW devices can be designed to function in various modes, such as delay lines, resonators, and filters. Each design serves distinct purposes, from filtering radio frequencies in communication systems to precise sensing in medical devices. The versatility in frequency response and bandwidth allows SAW technology to address different challenges across industries, making it a valuable asset in today’s technological landscape.

In summary, the reveal how mechanical vibrations in piezoelectric materials can be harnessed for advanced sensing and signal processing. By understanding these principles, developers and researchers can innovate and improve upon current applications, pushing the boundaries of what’s possible in various fields.

Comparative Analysis: SAW vs. Other Technologies

Surface Acoustic Wave (SAW) technology has carved a niche for itself in various applications, primarily due to its unique properties, such as high sensitivity and compactness. When comparing SAW technology with other sensing and signal processing methods, we see distinct advantages and some limitations shaped by the operational principles of each technology.

One notable comparison is between SAW devices and traditional bulk acoustic wave (BAW) devices. While both utilize acoustic waves, BAW operates on mechanical waves that travel through the material’s bulk rather than its surface. Though BAW can achieve higher performance at lower frequencies, SAW devices are typically more sensitive to changes in their environment. This heightened sensitivity is crucial in applications like environmental sensing, where minute changes need to be detected. Additionally, the smaller wavelength of SAW waves allows for smaller and more integrated devices, making them suitable for modern compact electronics.

Another strong contender in the field is optical sensing technologies. For instance, fiber optic sensors offer distinct advantages in terms of immunity to electromagnetic interference and the ability to transmit data over long distances with minimal loss. However, they often require complex and expensive setups, which can limit their practicality in certain applications. In contrast, SAW devices offer a more straightforward solution for many applications, especially in temperature sensing and pressure monitoring, where they provide high accuracy and reliability in a more compact and cost-effective form factor.

Performance Metrics

When evaluating these technologies, consider key performance metrics that can influence your choice depending on the application:

- Sensitivity: SAW devices typically exhibit higher sensitivity compared to BAW and optical sensors, making them ideal for precise measurements.

- Size and Integration: SAW technology can be miniaturized effectively, facilitating integration into small devices, whereas optical sensors tend to be bulkier.

- Cost: SAW devices are often less expensive to produce compared to the complex setups required for optical systems, making them accessible for a broader range of applications.

- Environmental Resistance: While SAW devices are robust, optical sensors excel in environments with high electromagnetic interference.

In summary, while Surface Acoustic Wave technology stands out for its sensitivity and ease of integration, traditional bulk acoustic waves and optical sensing technologies continue to hold their ground in specific niches. Understanding these comparative aspects allows innovators and engineers to make informed choices about integrating SAW technology based on the demands of their applications and environments.

Design and Fabrication of SAW Devices

The creation of Surface Acoustic Wave (SAW) devices is a fascinating blend of advanced materials science and precise engineering. At the heart of SAW technology lies the need for high-quality substrates, typically made from piezoelectric materials such as lithium niobate or quartz. These materials are selected for their ability to convert electrical signals into mechanical waves. The choice of substrate directly influences the performance characteristics of the SAW device, such as sensitivity and frequency response.

Fabrication begins with the preparation of the piezoelectric substrate. The surface is meticulously cleaved and polished to ensure it is free of imperfections, which could otherwise disrupt wave propagation. Following this, thin metal films are deposited onto the substrate, commonly using techniques like sputtering or electron beam evaporation. These metal films, typically composed of aluminum or gold, form interdigitated transducers (IDTs), which are crucial for generating and receiving the surface acoustic waves. The design of these IDTs, including the number of fingers and spacing, is carefully calibrated to achieve the desired performance metrics.

Once the IDTs are fabricated, they are often integrated into various electronic and sensor systems. This integration may involve further miniaturization and packaging processes to enhance usability in real-world applications. As SAW devices must often operate under varying environmental conditions, the encapsulation materials used can significantly impact their resilience and performance stability.

Key Considerations in Design and Fabrication

In the design phase, engineers must consider several factors:

- Frequency Range: The operating frequency of SAW devices typically ranges from a few MHz to several GHz, depending on the application. Design parameters must align with this frequency range to ensure optimal performance.

- Device Size: One of the pivotal advantages of SAW technology is its miniaturization capability. Engineers often aim for compact designs that maintain performance without sacrificing reliability.

- Environmental Factors: Devices should be designed to withstand factors like humidity, temperature fluctuations, and possible mechanical stress. Selection of appropriate encapsulation is critical.

In summary, the involve a meticulous process that merges materials science with innovative engineering. Each decision, from material selection to IDT design, critically influences the device’s efficacy, adaptability, and potential applications across industries such as telecommunications, healthcare, and environmental monitoring. This careful balancing of form and function is what positions SAW technology as a go-to solution for precision measurement and control.

Challenges and Limitations of SAW Technology

Despite the numerous advantages that Surface Acoustic Wave (SAW) technology offers, it is not without its challenges and limitations. Recognizing these can guide users and developers in making informed decisions regarding its application. One of the primary concerns revolves around the sensitivity of SAW devices to environmental conditions. Variations in temperature, humidity, and pressure can significantly affect the performance and accuracy of SAW sensors. For example, changes in temperature can cause expansion or contraction of the piezoelectric materials, which in turn alters wave propagation and disrupts the measurement accuracy.

Another important aspect to consider is the material constraints associated with SAW devices. While piezoelectric substrates like lithium niobate and quartz are excellent for generating surface waves, they can be brittle. This brittleness can limit the applicability of SAW devices in harsh or demanding environments where physical shocks or strains are expected. As a result, engineers must consider integration solutions that can mitigate these risks, such as protective coatings or shock-absorbing mounting techniques.

Furthermore, the complexity of fabricating high-quality SAW devices can also present challenges. The precision required in the design and construction of interdigitated transducers (IDTs) is substantial, and any deviation from the specifications can lead to suboptimal performance. Additionally, the processes required to achieve this level of precision can be cost-prohibitive, particularly for small-scale manufacturers or startups. As a consequence, the initial investment in SAW-based systems might outweigh their perceived benefits compared to simpler measurement solutions.

Trade-offs in Performance

It’s also crucial to highlight the trade-offs between sensitivity and operating range. While SAW devices excel in certain frequency ranges, their performance can diminish when operating beyond these parameters, limiting their versatility. Users looking for broad-spectrum applications may find this a significant limitation. Moreover, as SAW technology continues to evolve, keeping pace with advancements in competing technologies such as optical or electromagnetic sensors is vital. These alternatives may offer superior features such as lower susceptibility to environmental factors or greater measurement fidelity.

In summary, while SAW technology is a powerful tool for a range of applications, understanding its challenges-such as vulnerability to environmental changes, material limitations, fabrication complexity, and performance trade-offs-is essential for optimizing device performance and ensuring successful implementation in real-world scenarios. Proper evaluation and mitigative measures can help navigate these challenges effectively.

Future Trends in Surface Acoustic Wave Innovation

As we move further into the era of smart technology and IoT (Internet of Things), Surface Acoustic Wave (SAW) technology is poised for significant advancements that could redefine its applications and efficacy. One of the most promising trends is the miniaturization of SAW devices, which enables their integration into smaller, more versatile platforms. This trend is crucial as devices become increasingly compact and lightweight, especially in consumer electronics, where space is at a premium. For example, SAW sensors could be embedded in smartphones, wearables, and various portable devices, enhancing functionality without sacrificing performance.

Advancements in Material Science are also paving the way for more robust SAW devices. Research into new piezoelectric materials, such as polymer-based substrates, could help mitigate issues related to brittleness and sensitivity to environmental conditions. The development of flexible and stretchable sensors could lead to innovative applications in wearable technology and flexible electronics. Imagine smart clothing that can monitor vital signs or environmental conditions, thanks to embedded SAW sensors that maintain accuracy under diverse physical conditions.

Integration with Other Technologies

The integration of SAW technology with other sensing modalities is another key trend. Hybrid systems that combine SAW with optical sensors, for instance, can leverage the strengths of both technologies, providing enhanced measurement capabilities. Such combinations could result in superior performance in fields like environmental monitoring and healthcare diagnostics, where precise, real-time data is essential. These hybrid devices can offer advantages such as lower costs, improved sensitivity, and greater resistance to environmental variability.

Moreover, as the demand for wireless solutions grows, we can expect to see SAW devices that function effectively in RF (radio frequency) applications. This includes the development of SAW filters that are essential for telecommunications, capable of handling higher frequencies and broader bandwidths. The push towards 5G technology highlights the importance of such innovations, as the network’s demands for speed and connectivity require advanced filtering solutions.

In conclusion, the future of Surface Acoustic Wave technology is bright, driven by advancements in materials, integration with other technologies, and a relentless pursuit of miniaturization. These trends not only promise enhanced performance in existing applications but also open up exciting new avenues for innovation that could impact various industries significantly. As researchers, engineers, and manufacturers explore these possibilities, the potential of SAW technology to play a pivotal role in the smart technology landscape is becoming increasingly clear.

Integration of SAW Technology in Industries

The adoption of Surface Acoustic Wave (SAW) technology across various industries signifies a notable shift towards precision, efficiency, and advanced sensing capabilities. One of the standout features of SAW devices is their ability to utilize the surface waves generated on piezoelectric materials, leading to innovative solutions in numerous fields. This technology is not only transforming traditional applications but also enabling new functionalities that meet the demands of modern technology landscapes.

In the telecommunications sector, SAW technology plays a pivotal role in the production of filtering devices, which are essential for managing radio frequency (RF) signals. These SAW filters are critical in ensuring clear communication by eliminating unwanted frequencies, thereby enhancing signal integrity. As we transition to 5G networks, the need for compact and effective filtering solutions has surged. SAW devices meet this demand by offering high selectivity and bandwidth handling capabilities, crucial for maintaining fast and reliable network performance.

Healthcare and Environmental Monitoring

The healthcare and environmental sectors are also leveraging SAW technology for its impressive sensing capabilities. SAW sensors can detect minuscule changes in environmental conditions or biochemical markers, making them invaluable in medical diagnostics and monitoring systems. For instance, wearable devices equipped with SAW sensors can continuously monitor vital signs, providing real-time health data that can alert users and healthcare providers during critical situations. Similarly, in environmental applications, SAW devices can measure air quality or pollutant levels with high sensitivity, offering vital data to support urban planning and public health decisions.

The versatility of SAW devices is further demonstrated in industrial automation where they serve as part of smart sensor networks. In manufacturing contexts, these sensors can monitor equipment vibrational patterns to predict maintenance needs, thereby minimizing downtime and optimizing operational efficiency. This predictive maintenance approach not only drives cost savings but also enhances safety by preventing catastrophic failures.

In summary, the integration of Surface Acoustic Wave technology across diverse industries underscores its significant impact on enhancing functionality and operational efficiency. As the technology continues to evolve, its applications are likely to expand even further, unlocking new possibilities that align with the trends of miniaturization and smart technology. Embracing SAW technology can provide industries with a competitive edge in the fast-evolving landscape of technological innovation.

Real-World Examples of SAW Applications

Surface Acoustic Wave (SAW) technology is making waves across numerous industries, offering innovative solutions that are both efficient and precise. One captivating example is the use of SAW devices in telecommunications. These devices, specifically in the form of SAW filters, are essential for managing radio frequency (RF) signals. They eliminate unwanted frequencies, ensuring clear transmissions in devices like smartphones and communication systems. As 5G technology rolls out, the compact nature and high selectivity of SAW devices are vital to addressing the increased demand for bandwidth and signal integrity.

Healthcare Innovations

In the healthcare sector, SAW technology is revolutionizing patient monitoring and diagnostics. For instance, wearable devices equipped with SAW sensors can continuously track vital signs such as heart rate and temperature. These sensors are not only highly sensitive but also provide real-time data, allowing for immediate alerts in case of critical health changes. This capability is particularly beneficial in managing chronic conditions, as timely data can lead to rapid interventions, ultimately improving patient outcomes.

Environmental Monitoring

Beyond healthcare, SAW devices are critical in environmental applications. They offer advanced sensing capabilities that detect pollutant levels in air quality monitoring systems. By accurately measuring environmental conditions, SAW sensors provide valuable insights that help urban planners and public health officials make informed decisions. For example, during high pollution periods, data from SAW sensors can guide public advisories and emergency responses to protect community health.

Industrial Applications

In industrial settings, SAW technology is becoming a cornerstone of smart manufacturing. These devices are integrated into predictive maintenance systems, where they monitor machinery conditions through vibrational analysis. By detecting anomalies early, companies can prevent equipment failures, significantly reducing downtime and maintenance costs. The application of SAW devices in this context enhances operational efficiency and safety, allowing for a more streamlined and reliable manufacturing process.

Overall, the real-world applications of SAW technology showcase its versatility and transformative potential across various fields. From enhancing communication systems to monitoring vital health metrics and ensuring environmental safety, SAW devices are proving crucial in navigating the complexities of modern technology landscapes.

How to Select the Right SAW Solution

Choosing the right Surface Acoustic Wave (SAW) solution can significantly impact the performance and efficiency of your application, whether it be in telecommunications, healthcare, or industrial environments. With a wide array of SAW devices available, selecting the most suitable option requires careful consideration of several factors specific to your needs. The first step is to define your application’s requirements, such as the desired frequency range, sensitivity, and environmental conditions. For instance, if you are working with RF signals in telecommunications, prioritizing devices with high frequency selectivity and low insertion loss will ensure clearer signal transmission.

Next, evaluate the design specifications of potential SAW devices. Consider aspects such as bandwidth and temperature stability, as these influence the reliability and accuracy of the sensors under operational conditions. For instance, in industrial settings where machinery operates in varying temperatures, choosing a SAW device designed for high-temperature resilience is crucial to maintain performance. Additionally, reviewing the integration compatibility of the chosen SAW components with existing systems is vital. Ensure that the interfaces and signals align seamlessly with your hardware and software to avoid costly modifications down the line.

Another essential factor is the vendor’s track record and support. Selecting a device from a reputable manufacturer not only assures quality but also offers access to technical support and documentation that can simplify troubleshooting and maintenance processes. Look for vendors that provide comprehensive specifications, application notes, and case studies showcasing real-world implementations of their SAW solutions. This insight can guide your decision-making process and facilitate a smoother integration into your specific application.

Ultimately, by clearly identifying your needs, scrutinizing design specifications, and collaborating with reliable suppliers, you will be well on your way to selecting the right SAW solution that meets both your technical demands and operational goals. With the right choice, you can harness the full potential of SAW technology to enhance performance and efficiency across your projects.

Glossary of Key Terms in SAW Technology

Defining the language of Surface Acoustic Wave (SAW) technology helps bridge the gap between theory and application, making the intricate world of acoustic waves more accessible. Here, some key terms are clarified to enhance understanding and foster informed discussions around SAW technology.

Key Terms in SAW Technology

- Surface Acoustic Wave (SAW): A type of mechanical wave that travels along the surface of a material, such as a piezoelectric crystal, propagating through deformations in the medium. This wave’s unique properties enable various applications, including sensors and filters.

- Piezoelectric Effect: The ability of certain materials to generate an electric charge in response to applied mechanical stress. This effect is crucial in SAW devices, enabling the conversion of electrical signals into mechanical waves and vice versa.

- Transducer: A device that converts one form of energy into another. In the context of SAW technology, transducers are used to generate and receive the surface acoustic waves, allowing for signal processing in various applications.

- Frequency Response: The measure of a device’s output spectrum in response to a given input signal. In SAW devices, this concept is critical for determining how well a device can filter or transmit specific frequency ranges.

- Insertion Loss: The reduction in signal strength resulting from the insertion of a device in a transmission line. A lower insertion loss indicates a more efficient device, essential for maintaining signal integrity in telecommunications.

- Bandpass Filter: A device that allows signals within a certain frequency range to pass while attenuating frequencies outside this range. SAW bandpass filters are widely used in RF applications due to their compact size and high selectivity.

- Temperature Coefficient: A parameter that indicates how sensitive a device’s performance is to temperature changes. In SAW devices, it directly affects frequency stability, making it critical for applications in varying temperature environments.

- Reflection Coefficient: A measure of the portion of a wave that is reflected back at an interface compared to the portion that is transmitted. This coefficient plays a significant role in the efficiency of SAW devices.

- Amplifier: An electronic device that increases the power of a signal. In SAW applications, amplifiers are often used to enhance the output signals from transducers.

- Acoustic Wave Filter: A device specifically designed to filter signals based on their wave properties. SAW filters are particularly valued for their precision and performance in mobile communication systems.

Grasping these fundamental terms will empower you as you dive deeper into the fascinating applications and advancements in SAW technology. Whether it’s developing a new sensor or improving telecommunications systems, understanding these concepts facilitates better decision-making and innovation in the field.

Faq

markdown

Q: What are surface acoustic waves (SAWs)?

A: Surface acoustic waves (SAWs) are sound waves that travel along the surface of a material. They are characterized by their propagation along the surface, where the energy is concentrated within a few wavelengths of the surface. This property makes SAWs effective for various sensing and signal processing applications.

Q: What are the key applications of surface acoustic wave technology?

A: SAW technology is commonly used in communications, sensors, and actuators. Key applications include RF filters in mobile devices, pressure sensors, and temperature sensors, enabling precise measurements and reliable performance in various industries.

Q: How does surface acoustic wave technology compare to other technologies?

A: Compared to other technologies like bulk acoustic wave (BAW) devices, SAWs offer advantages in size, cost, and frequency performance. They are particularly favored in low-power applications due to their efficiency and the ability to integrate with CMOS technology.

Q: What are the advantages of using SAW devices?

A: SAW devices are advantageous due to their high sensitivity, low power consumption, and small form factor. They exhibit excellent frequency stability and can operate in harsh environments, making them suitable for a wide range of applications including telecommunications and industrial monitoring.

Q: What challenges does SAW technology face?

A: Despite its advantages, SAW technology faces challenges such as temperature sensitivity and limited bandwidth. These factors can affect the performance of SAW devices, especially in varying environmental conditions, necessitating careful design and calibration.

Q: How are SAW devices fabricated?

A: The fabrication of SAW devices typically involves lithographic techniques to create interdigitated transducers on piezoelectric substrates. This process allows precise control over electrode design, enhancing the acoustic wave's performance and efficiency.

Q: What future trends are emerging in SAW technology?

A: Future trends in SAW technology include the development of miniaturized sensors, integration with IoT devices, and advancements in materials that enhance performance. These innovations are expected to expand the use of SAWs in emerging applications such as smart cities and healthcare monitoring.

Q: How can I select the right SAW solution for my project?

A: To select the right SAW solution, consider factors like application requirements, environmental conditions, and cost constraints. It's essential to evaluate the performance specifications and reliability of different SAW devices to ensure they meet your specific needs.

To Conclude

Thank you for exploring the fascinating world of Surface Acoustic Wave (SAW) technology with us! This innovative approach not only enhances sensor applications but also improves touch screen performance significantly. If you found this overview valuable, consider diving deeper into related topics such as the applications of SAW devices in various industries or our comprehensive guide on acoustic wave sensors.

Act now-subscribe to our newsletter for the latest insights and developments in technology, ensuring you stay ahead in this rapidly evolving field. We’d love to hear your thoughts or questions, so feel free to leave a comment below or share this article with colleagues who might benefit from understanding SAW technology. Your engagement helps us grow and provide even more content that empowers tech enthusiasts and professionals alike!